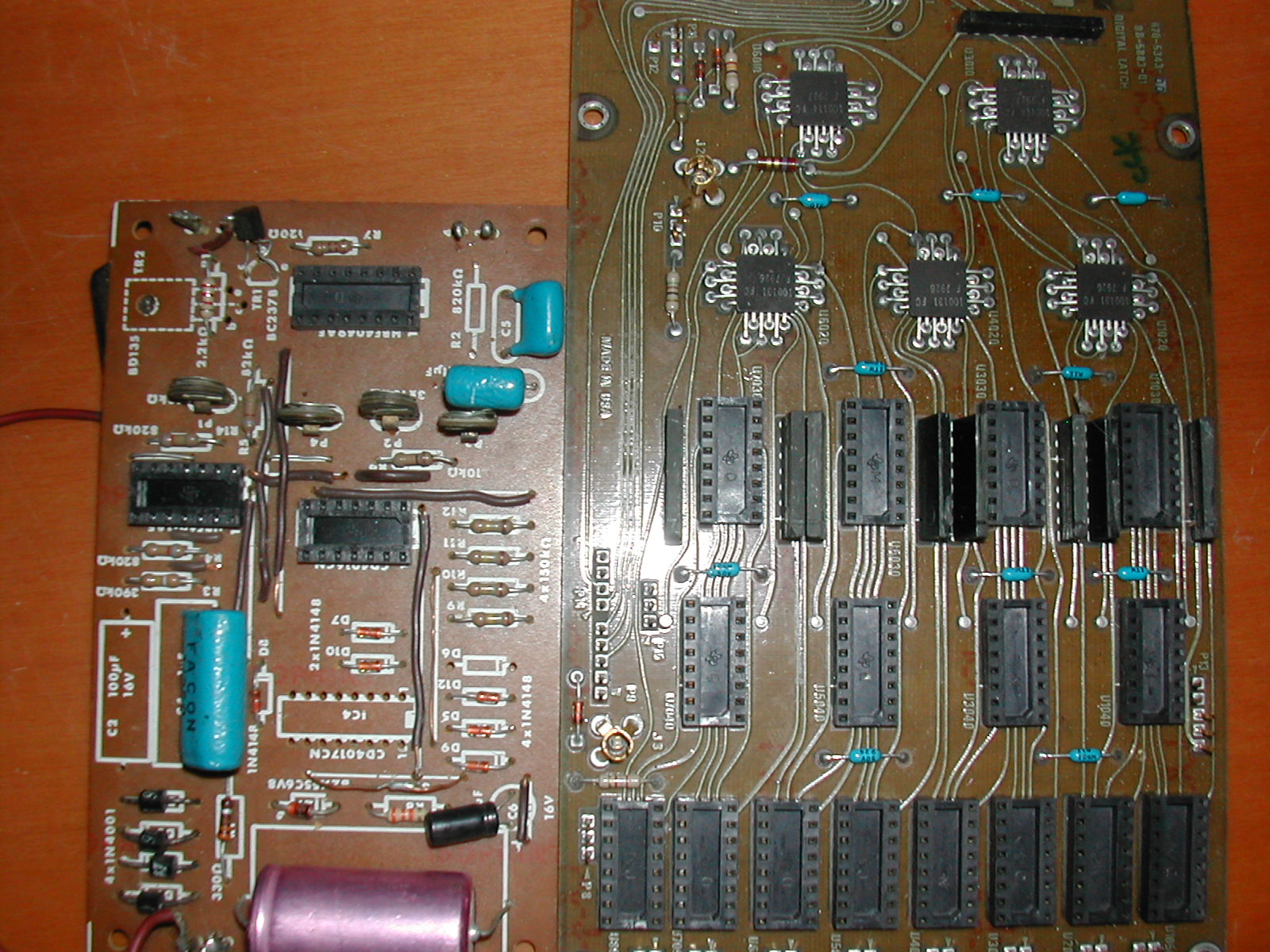

Found these boards at a HAM Radio fest, abandoned in a crate...

of course, given the rarity of TI sockets, I immediately thought of re-using them for an Apple-1 replica.

What could be the best way to desolder the sockets without damaging them?

I have a chinese desoldering gun that's acceptable on discrete components but I don't trust it much on DIL components.

I was thinking about a hot air gun but I don't know how the plastics and mylar backing could react.

Considered a T-shaped iron tip but they seem uncommon nowadays so... perhaps desolder wick and much patience?

Hello Gabriele72,

in fact all methods mentioned above would be a bad idea and damage the case of that sockets.

At the other hand the sockets can easily be demounted before desoldering of the pinclamps

because the pinclamps are only fixed by the mylar backing in the socket.

Another problem is that the pins of the pinclamps break easy under stress ....

therefor you should avoid any kind of stress to them and therfor be very gentle in removal procedure....

- but first desolder the capacitors and wires away that are placed above and below of the sockets.

Then the best attempt will be:

Lift up gently - only the socketcases with the flat side of a Blade or thin screwdriver by slipping below the case leaving the pinclamps and mylarbacking in place,

then gently pull with a tweezer at the side the mylarbacking away by gently sliding out from its position,

and then desolder each pinclamp

- by fixing the board in a very heavy jaw vice and

- picking the pinclamp with a tweezer

- and heating it´s pin at solderside and

- gently pulling out the pinclamp.

Reinsert that desoldered pinclamp in the socketcase and

remove with this procedure every pinclamp, till all have been extracted and then reinserted in the socketcase and

- finally slip in the mylarbacking to the socket in place with the tweezer.

pay attention while reinserting the pinclamps in the socket

- that the sliding notch for the mylar backing is always orientated correct position

- towards center of the socket.....

this takes much time - but by this procedure neither the socketcase nor the mylar will be stressed by any kind of heat!

And besides you have the chance to examine each pinclamp for oxydated plaque and cleaning up

before reinserting them in the socketcase....

sincerely speedyG

Hi,

good advice, your solution is viable and since I paid nothing for those boards, I feel like experimenting.

I'm finding that is almost impossible to apply the correct amount of force so while I'm lifting up with one hand I keep a finger on the socket, thus preventing it to pop out and bend or break the pins.

Curiosly, the sockets from the bigger board have no mylar backing. According to the datecodes on the ICs, those boards appear to be from 1979.

BTW, what could be a good way to clean the pins from alloy residues?

Speedy,

I have used that "Mylar" removal trick to fix worn TI sockets without desoldering and replacing them. You remove the plastic casing and then using dental tool rebend the pin contacts and then reassemble the socket. a giant pain, but you get to keep the socket original. I've tried explaining this to some people before but your diagrams/pictures are great references to explain the disassembly procedure.

Cheers,

Corey

Hello Gabriele72,

first: the force required to lift the socketcases is very low.... at the other hand the pinclamps are very sensible to

break .... so lifting up the socket at on side and then lifting it at the other side is the only way to protect the pinclamps from breaking.....

cleaning the pinclamps

- well first clean them from dirt with IPA ( isopropylalcohol )and

then - if needed -

gently cleaning the contact area with very fine sandpaper ( grade 400 or 600 )

i have made a kind of "double-cut file", by attaching fine sandpaper to thin woodenplate ( 1,5 mm ) at both sides

with thin slice of glue and waiting for it to dry completely .....

to Corey,

well dental tools are of course a fantastic aiding tool set, but lots of people don´t have access to this

kind of tools.... next best availiable source will be tools from scale modelling or model making.....

some tools from fine mechanical work will do too....

and some can be made "homebrew" like the file i explained above....

i made a thin board covered with sandpaper at both sides - and then cutted it to stripes....

sincerely speedyG

I use a slightly different ending now, the pins you can buy for 1p each, so no need to de-solder you just need to but new pins.

The Pins come with newer sockets from TI, the ones you can get from almost anywhere, they have he mylar base too just the wrong plastic moulding

Following advices from SpeedyG and Clint I've been able to recover all of the sockets but one (my hand slipped at first attempt...), plus 8 more from old SWTPC boards (replaced with open frame ones as Clint suggested, without even touching the desoldering gun).

Thanks! I'm now almost halfway in the hunt for sockets...