WaterCooledG4

“It just works."? That’s the slogan. Here’s my saga of where it just didn’t work. Of course, once you get into the upgrading game rather than just happily paying the cost of a new system, all bets are off and you must be comfortable resolving problems, whatever problems, on your own. Or give up and accept the performance level of your stock system. But what fun is that?

And so it begins. (As documented by excerpts from some emails and project notes.)

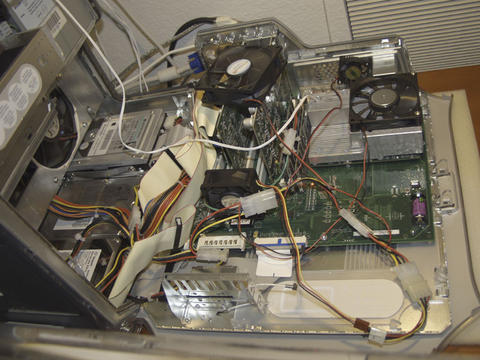

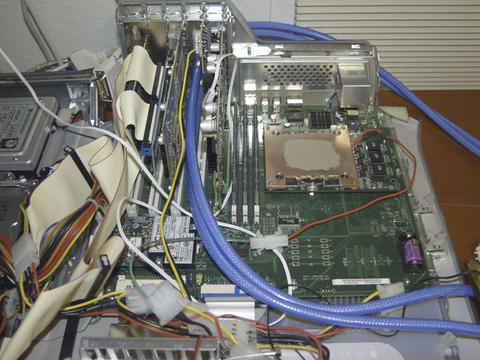

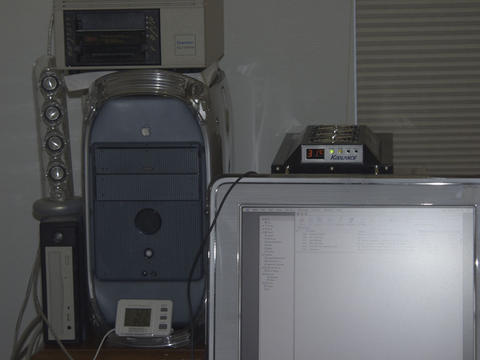

Today I received a processor upgrade that I had been waiting a few months to become available. (It had actually dropped a third in price between product announcement and product availability.) The original system is a PowerMac Digital Audio 533mhz dual processor. And the upgrade was supposed to be a 1.2ghzDP. Well imagine my glee when I powered it up and it is 1.33ghz clock rate. Ran a few benchmarks and all looked great. Then it crashed. Bummer. It is overheating. So, do I do the sensible thing and call for an RMA for this defective product? No, not me. I decide that I really like having an upgrade that makes this machine almost as fast as the fastest of the new ones, if I can make it work reliably. [Note: At this point in the saga I didn’t know that all these CPU upgrade modules were shipping at the 1.33ghz speed. I assumed a ‘fluke’ had landed on my doorstep and I had better keep it.] So, since it can't stay cool enough with the case closed up, I take the approach of moving the bastard off the floor onto the desktop where I can leave it open all the time, with an assortment of extra fans. It's that big heat sink which isn't getting cooled adequately for this 'factory overclocked' job. The other fans are just there since the PCI cards no longer benefit from case flow cooling. [picture 1]

The configuration evolved from that in the picture using the single fan supplied in the upgrade kit to having two three inch fans 'pancaked' on top of the heat sink and that is keeping it going. With a full max heat producing number crunching load the thermocouple on the sink measures 17F above ambient. System crashes at 102F. Just the one fan, the one in the picture - the one it shipped with, can only keep it to about 24F above ambient. And the case tolerances are such that that depth fan is the largest which can be installed and close up the case. (I tried .) The extra quarter inch of a full versus half depth fan is just exactly too much for the case to hinge shut. I doubt if the case interior is keeping below an ambient of 80F anyway.

Anyhow, keeping it below 100F it has run for hours under full load and is 2.5 times faster than before. (Actually somewhat more for most usage because of the newer generation PowerPC chip and more cache.) A nice upgrade. At less than half the cost of a comparable performance new machine. (Of course, you can run the new ones with the case closed .)

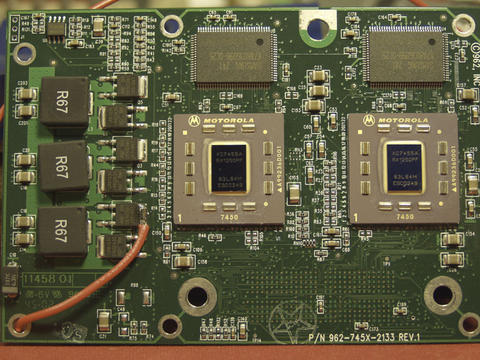

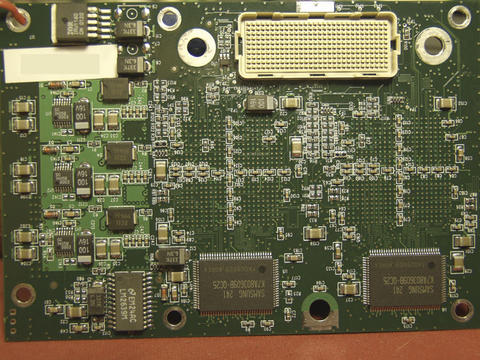

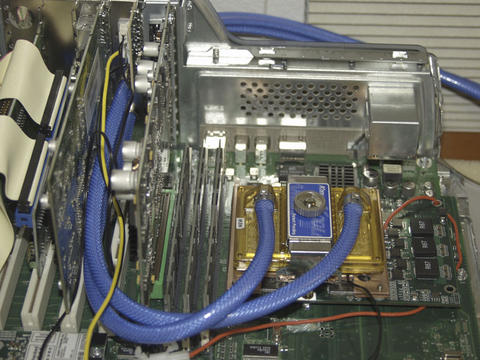

So at that point I had it running. What was running? OK, here are a few pictures of the PowerLogix Series 133 1.2ghz dual processor upgrade module which you see installed in the Digital Audio PowerMac in picture 1.

However, I didn’t stay a happy camper for long with that solution. While the ganged up three inch fans running at full speed did keep it operational, barely, there were several significant problems with this approach.

- Marginal thermal conditions — The room the PowerMac is in ranges about eight to fifteen degrees F warmer during the Summer. Air conditioning is more expensive than gas heat. And I like the low to mid eighties.

- Noise — Move enough air and you get more cooling. And more noise. Much more noise.

- Open case on desktop — This just ain’t right.

So now on to stage two. ‘The Great Air-Cooling Effort’.

picture 8 (Front view - looking down over monitor)

Picture 7 shows three things (of interest) visible here.

- The original 3in fan removed. 'Custom' duct fabricated from cardboard and shipping tape to mate a 5in fan to a 3in receptacle on top of the heat sink. The foam square squeezes around the fan which is press fitted into the top of the duct and creates an air tight seal. Bottom of the duct is taped around the heat sink to create an air tight seal. All air is forced into heat sink fins. Fan is powered full speed at 12vdc.

- 3in fan powered at 7vdc blowing over PCI cards for their cooling.

- Sheet of cardboard (back in chassis) is redirecting air from internal chassis 5in fan (12vdc, but thermal controlled - runs slow/quiet with case open) over the four internal disk drives.

In picture 8 the main thing visible is the 5in fan (at 7vdc) sitting on top of the PCI cards blowing away from the big heat sink. Without this fan there was a substantial re-induction of hot air back into the main heat sink fan.

And here in pictures 9 and 10 you see the new 'case annex' fabricated from stacked up old shelving boards. This substantially contains the remaining sound. And the shades closed (as they normally are) also contribute to sound reduction. Zoom in and you can see a sub 90 degree F reading from the thermocouple on the heat sink. (BTW, those digital indoor/outdoor thermometers are great for playing this kind of game and cost about $10.)

After everything settled down I get 91.4F on the heat sink with ambient of 73.0F. Since this room is typically 80-82F in the Summer (which is my favorite temperature range) this would result in about a 102F heat sink reading, assuming linear scaling. Empirical tests have the computer starting to get flakey at 105F as measured at the current thermocouple position on the heat sink. “Walkin’ on a thin line.�?

Noise level is about the same as it was for this system before all these shenanigans started. That is, about the same as the stock G4 Digital Audio.

So, again, I had improved my situation (if you can call it that), but I didn’t stay content for long. I knew there was a better way.

A detour through PC land.

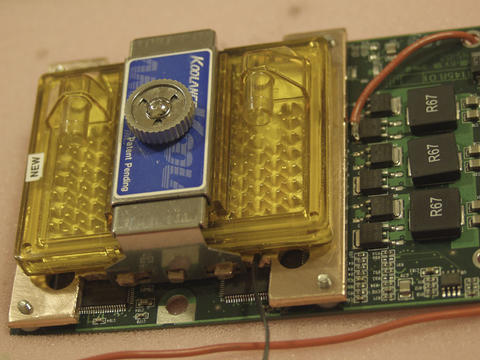

I’m quite familiar with the possibilities of, and tradeoffs of, air cooling a computer system. And with my Athlon system I had recently gotten fed up with the noise and hassles involved and made the decision to try a water cooling solution. Enter the “Koolance EXOS - Liquid Cooling System�?. Hit Google with the appropriate key words and you can find several extensive reviews of this kit on the sites that cater to the Intel/AMD overclocking crowd. Here in the States it can be had for about $300 delivered. A nice-to-have feature on the PC side of this kit makes it pretty much the only viable kit for the PowerMac. That is, it is a self contained kit residing external to the computer case with a PCI card bracket to bring power and water in/out of the case. On the PC side this is merely a convenience since there is usually plenty of room in tower cases to install almost anything. However, there is no spare space in a PowerMac to accommodate a water reservoir, pump and radiator.

Pictures 11 and 12 show this kit installed on an Athlon 2000+ system. (Which is, yes, overclocked .)

As of today, these are good links for information about the unit. I’m not going to review it again, just show how I’ve used it.

http://koolance.com/products/product.html?code=EXT-A01

http://www.hardocp.com/article.html?art=Mzc2

http://www.overclockers.com/articles636/index.asp

Now those of you familiar with AMD (or pre-Pentium 4 Intel) systems know that there are a row of three tabs on each side of the CPU socket (socket-462). The most common method of mounting a heat sink on those systems is by a device which hooks over one of more of those tabs. Obviously, there are no such tabs in a Macintosh. Eureka! An adapter is needed.

Now no heat sink made for a single processor AMD/Intel system is going to fit properly on two PPC processors. But my theory was that a copper plate which spanned both PPC chips could be cooled by a water block style heat sink designed for AMD/Intel systems. Since the PowerPC microprocessors heat disspation pretty much tops out at about 25 watts per CPU, for an aggregate max of 50 watts to handle, and the AMD Palomino microprocessor dissipates 70 watts running at stock voltage and speed, I felt on pretty safe ground even if there was some cooling inefficiency due to the intermediary copper plate and an additional contact surface.

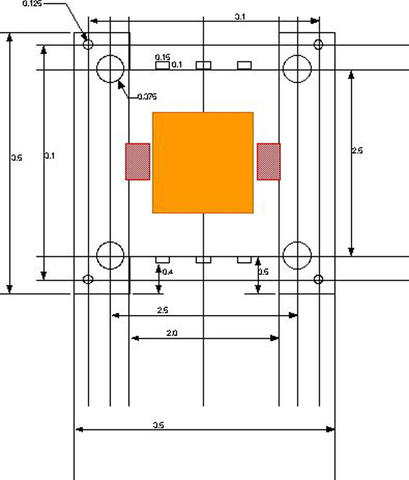

Here is what went into creating drawing 1.

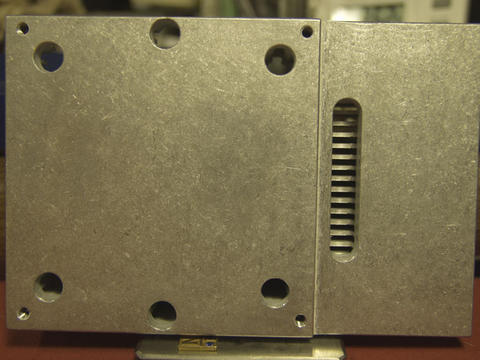

I found an engineering drawing of the standard socket-462 socket with detailed dimensions. This was used for the portion of the adapter for the Koolance water block mounting. I measured the relevant portion of the PowerLogix heat sink for its overall dimensions and holes for both mounting the CPU module to the heat sink (in this case ‘water block adapter plate’) and for fastening the CPU module + heat sink assembly to the Apple logic board. ‘Extra’ (irrelevant to construction) information on the drawing shows the footprints of the Koolance 200G water block (orange) and the two PPC chips (red).

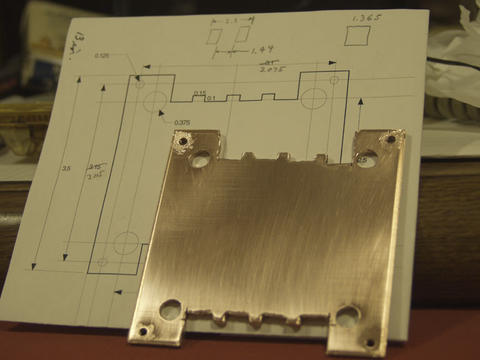

Once I had this drawing (plan, it helps to have a plan ) in hand I set out to find a 3.5 inch square by 1/8 inch thick piece of flat copper plate. Which I found locally for $7.03 + tax each. [picture 13] And after only about a half dozen hours of labor with the universal tool (Dremel), and some easy hole drilling, I had an adapter plate fabricated to my custom specifications. [picture 14] (NOTE: Use 1/8 inch drill bit on four ‘outside’ holes and the screws supplied with the PowerLogix kit (or any of same spec) will be able to self tap the soft copper.)

An alternative.

Some Athlon motherboards provide an alternative mounting mechanism of four holes in the motherboard offset around the CPU socket. And some air cooled heat sinks, and more relevantly, some water blocks, are designed to use this form of mounting. Using this mounting technique, requiring only that four holes of proper diameter in the right locations be drilled, would be vastly easier than carving the copper plate to look like an outline of a socket-462. I highly recommend you look into this if you tackle such a project. I only went with this approach because I already had the Koolance kit in house and wanted to reuse it to test the validity of the approach.

For example, in just doing a quick search, this caught my eye:

http://dtekcustoms.safeshopper.com

picture 15: TC-4 Rev 2 Aluminum Topped Waterblock

This water block from D-TEK costs about the same as the Koolance 200G and, if it would work (I see no reason why it wouldn’t, I would like to see a picture of the bottom) the different mounting method would make it trivial instead of grueling to make that adapter plate. BTW, the price I mentioned above of $300 for the Koolance EXOS delivered includes the cost of the water block, but the block is in addition to the price of the EXOS itself. In other words, there is no reason not to buy the EXOS unit alone and mix/match another vendor’s water block. Caveat, if you do this you do have the responsibility to ensure that the connector tubing inner/outer diameter is compatible with all the pieces.

But that’s not what I did. That’s what I shoulda done. Now I’ll get back to what I did do.

Water cooling a G4 dual processor.

Picture 16 shows the adapter plate fitted to the CPU module with four screws which self tapped the soft copper. Three screws are used to secure this assembly to the logic board. Two screws fit through the holes in the copper on the bottom/near side of the picture and the third mount point is visible at the top/rear where the copper has been removed to make a ‘socket-462’ shape. NOTE: WARNING: CAUTION: (got your attention ) There are four plastic shims which come with the PowerLogix upgrade. When you remove the original heat sink from the CPU module be sure to save these. They provide exactly the right spacing between the circuit board the PPC chips are mounted on the bottom surface of the heat sink. IF YOU ATTEMPT ASSEMBLY OF AN ADAPTER PLATE WITHOUT THESE SPACERS YOU WILL LIKELY DESTROY THE CPU MODULE.

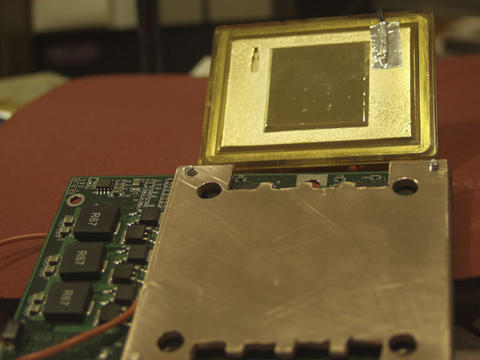

In picture 17 the Koolance 200G water block is positioned above the CPU module with adapter plate mounted. Note that barely visible on the lower half of the water block is an 'imprint' of an Athlon Palomino CPU die. This Koolance Exos kit was shifted from an Athlon Palomino 2000+ (1660mhz) overclocked to 1760mhz. Also visible is the thermocouple supplied with the EXOS kit. (Under the silver tape on the top right of the water block.)

Picture 18 shows the Koolance 200G water block fitted on the adapter plate with the Koolance clip. Note that this is just a fit test. The CPU module and adapter plate assembly must be screwed to the logic board before this can be done for real since the water block obscures two of the CPU module to logic board mounting points. The third mount point, which is not blocked, is visible at the bottom/front of the picture.

Up to now the pictures were taken as test fittings were performed to ensure physical tolerances were being met. I.e., just to see if the pieces physically fit . But in picture 19 you can see that things are getting serious. Thermal paste has been applied to both PPC CPU chips before the adapter plate was screwed to the CPU module and with the CPU module and adapter plate assembly secured to the logic board thermal paste has been applied to the top surface preparatory to clamping the water block down on top of the paste.

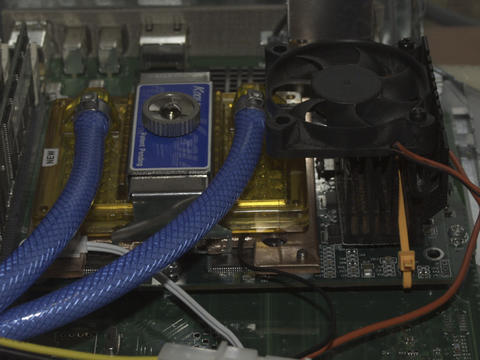

Picture 20 has it all mounted on the logic board. Hoses attached. Filled with water and pre-charged all according to the Koolance instructions. Well, almost according to Koolance instructions. They provide a jumper and describe a way to jumper an ATX power supply to run the pumps with the logic board (mother board for PC people) disconnected from the power supply. Rather than do this I just used an old spare AT style power supply laying around to power up the EXOS system and get it properly charged with water. However you do it, it is crucial that for initial operation the EXOS is operated before power is applied to the chips it is to cool so that air can be purged from the system and the reservoir is topped off. BTW, this is only for the initial start-up. Subsequently it powers up and down along with the computer.

Checking for leaks isn’t such a bad idea either .

In fact, I completely assembled this cooling system and let it run on the kitchen counter for about eight hours before I installed it in the case. Tip: You can’t remove the hoses from the water block once installed. (Well, you can, but it is a royal pain and you need to cut off about the last half inch of hose each time. And the clamps only have a limited number of removal/reapplications.) However, it is easy to remove the other end of the hose that use compression fittings for attaching to the EXOS main unit. These come off easy and are easy to reapply. So just do that and snake the hoses through the PCI cover plate the ‘long way around’ when you are ready for final assembly.

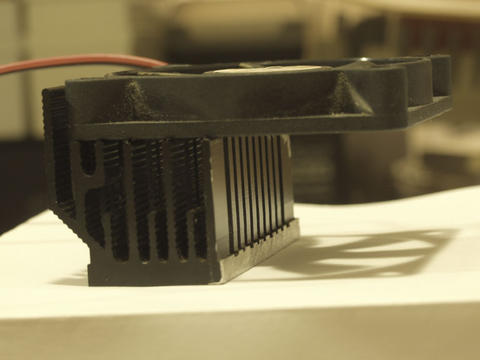

Ready for test run. Dang! Those three "R67" chips get far too hot to touch. (See pictures 2, 16, 17, 18, 20.) Power down and analyze the situation. The original heat sink did not sit on these hot critters. (See pictures 1 and 6.) However, there is a cutout in that heat sink which allows some air to flow through the bottom and out of it over this area. OK. Something needs to be done to keep these power chips cooled, a little.

Wahlah! Custom cooling for the voltage regulator chips shown in pictures 21 and 22. Fifteen minutes with a hacksaw and an old K6 heat sink becomes half the width and a perfect fit. Fan provides air flow for the heat sink and also blows over some 'lessor' voltage regulators which also run hot. But not nearly as hot as the big guys. Anyway, the original heat sink/fan blew air over them, so I blow air over them.

Case closed. After several hours of runtime under full load the Koolance temperature reading (measured by a thermocouple on the water block) has stabilized at 32C/91F. The thermocouple mounted on the adapter plate reads 37C/98F. The 7F delta was pretty constant as the temps slowly ramp up from a cold start.

Noise level. Not silent, but pleasantly low. There is still the power supply fan (which I had already replaced with a thermal controlled and quieter fan), the 12in case fan (which is thermo controlled and I'm now running at 7v instead of 12v), and the four disk drives. The Koolance EXOS itself is almost inaudible. I can now monitor boot up activity by listening to the head seeks on the drives .

After a couple of days running the system on the desk during a ‘shake down period’ I moved the system back to its original location on the floor beside the desk. Shown here in picture 25. The system has been running twenty four hours a day for a week now running compute/numerically intensive tasks. (Distributed computing number crunchers in addition to normal duty. An ecc2-109 client for a few days and rc5-72 for the last couple of days.) It is important to run full system stress inducing code on a system after doing any cooling modifications because such software causes the CPU chips to generate substantially more heat than when they sit idle.

OK. I know, I know. You want to know what that box with the two fans is doing sitting on top of the EXOS. It isn’t necessary. Really. I’ve just got a lust to tinker.

To test whether there was any reinduction of exhaust air I folded a piece of cardboard to duct the exhaust well beyond where it might be possible for any to flow back into the intake. This actually did make a difference of about 2 degrees C measured by the water block thermocouple - the reading on the front of the EXOS. With this duct sitting there I happened to notice that it was just the right size to fit a five inch fan into. (There were fans laying all over my desk from the prior air-cooling efforts.) And a large diameter fan running at low speed makes very little noise. So, just to see what the effect might be I put two 5in (120mm) fans in the top of the duct (with foam applied as needed for physical fit and moderate ‘air-tightness’) and powered them with a 9vdc transformer. This added an insignificant amount of noise (barely audible difference as an A/B test with them on/off), and an additional 5 degrees C reduction in water block temperature. Not needed. But, hey, cooler is always better, right ? And it will provide that much more margin for the Summer when I like the room to be about 10 degrees F warmer than it is now.

Epilog

Well, that was fun. And it is just as fun to be actually using a computer which is over twice as fast as what I started with and provides an office environment where I have no distracting howling beasts which I just have to live with unless I want to start doing all my work on notebook class hardware. My workspace has the 1.33ghzDP Mac on the left side of the desk and a 2100+ Athlon on the right. Both water cooled. And it is the quietest work environment I’ve had in many years.

Final Statement

OK. Now that you’ve seen this saga it should be abundantly clear to everyone that no sane person would do such a thing. I am not recommending that you take any such action. I am not responsible if you try any stupid stunts, even if they bear some resemblence to stupid stunts I may have performed, and damage of any sort happens to your hardware, your software, your data, your rug, your real estate, your person, or your state of mind. If you open your box, anything which might happen is your responsibility.

Ron Gazaway

Austin, TX

March 5, 2003

Comments

whoa... over 2 megabytes of p

whoa... over 2 megabytes of pics on one page :o

Hmm...

That was interesting...

idea

this inspires me. im stuck with a ruined but running ibook g4 and a slow but attractive powerbook g3 wallstreet, and id like something new. this inspires me because i like the older powermac g4s and would like to buy, upgrade, and customize one. the fatass fans on that pc case are a nice touch that inspired this...mainly. so maybe im up for a nice 2ghz tangerine powermac g4 with g5 style cooling. sounds like a nice gaming system that could outperform my bros custom pc.

i do like it

ok my last comment was really stupid. i just scrolled throught the images before wrtiting my comment. i do like this hack. it seems economical to me and would be great for my brother (his case has an amd and at least five fans so its really loud) because he plays games on his PC (ugh PC) and i plan to build a computer for the same purposes with his old motherboard (made by the same company with what he has in his computer now) and run BeOS on it (this looks like a great running system). wish me luck.

very informative, very intere

very informative, very interesting.

i would do this to mt own g4, BUT i dont want an ugly external box added.

oh, by the way, how many HDDs you got in there? 6?

interested on how you mounted them all

simon

I remember seeing a water coo

I remember seeing a water cooling system that is mounted in 2 hard drive bays.. not sure if it would work in a Powermac though.

there is one that fits anywhe

there is one that fits anywhere you can fit a pump and an 80mm fan in the case.

here: http://www.coolerguys.com/840556018735.html

or this single-unit (fan, pump, and rad are all in one): http://www.coolerguys.com/840556000389.html

Those three "R67" chips

Great Project.

The R67 chips are actualy coils or inductors, used to smooth signals or control voltage spikes. They are probably getting hot due to the "overclocking". Cooling these is a good idea, if they overheat they will burn up and the computer will go haywire or die.