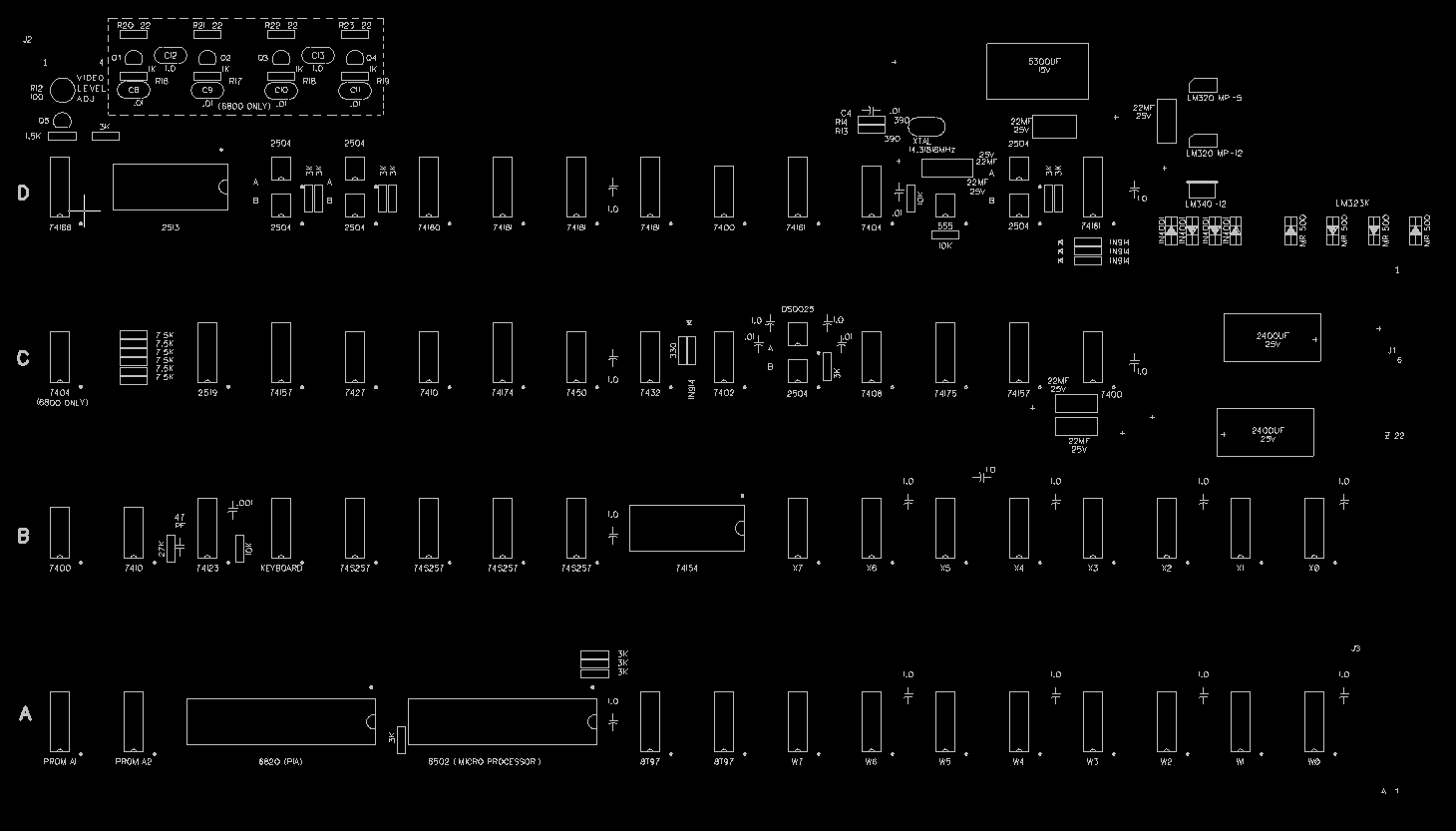

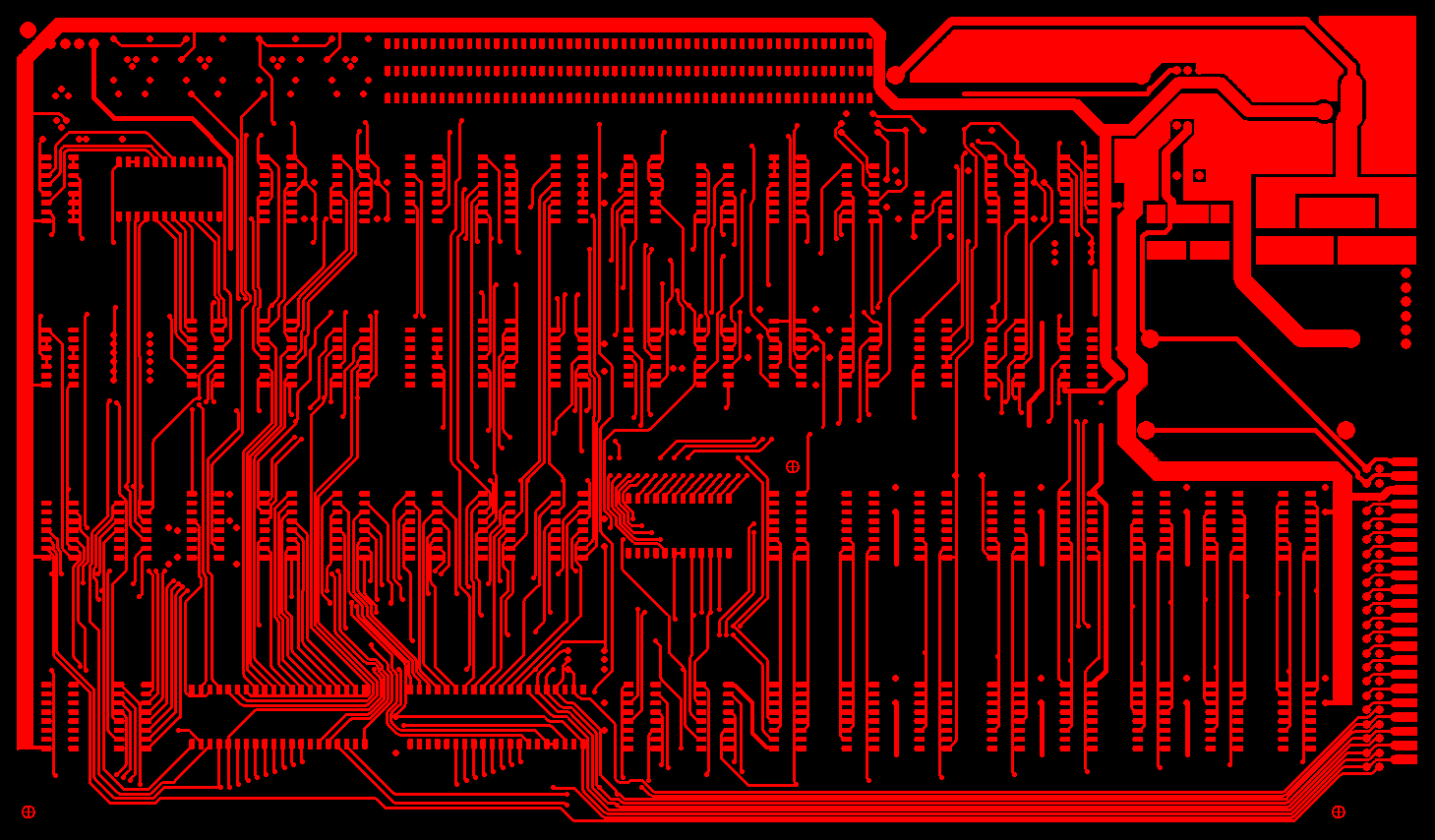

Hey everyone! So I have very exciting news. After about at least 100 hours of total work I have completed the first NEW Revision of the Russian Apple-1 Replica Files. These files were entirely (modified) by only me, the goal is to get this replica board to look as CLOSE as it can to the original, and I think this revision takes a REALLY great step towards making that happen! To notice each modification you have to compare the original open source files to mine.

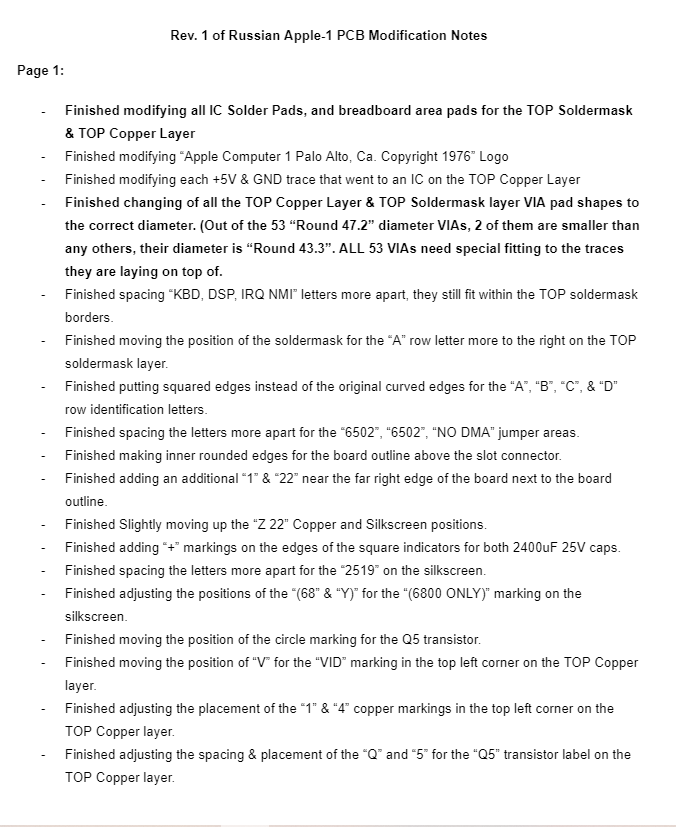

So, here’s the Rev. 1 files I have posted a link to my Google Drive, here is some photos of how it looks in my CAD software below. Also, I’ve posted an updated 2 page document with all my notes of the modifications that I have finished doing so far. I would kindly like the credit for the modifications if anyone decides to use these files. Have at it!

P.S. I have already started work on Rev. 2 a little over a week ago, and it's looking great!!

https://drive.google.com/file/d/1Vqv--zUIUIRCbdgQH321WBE9jkb27d_h/view?fbclid=IwAR28fK152hAN9Ff0Ezd533CcMtyPPtKNr3KVebv0grpsvcM3NU8y_sbwj7g

It's great that somebody finally volunteered to get the Open Source Gerbers into a better shape. This is not meant to slam the great work of the Russian guy who made and released these Gerbers, not at all. Misha did a great job and the whole worldwide Apple-1 crowd should cherish and praise him forever to have made Apple-1 clone building more affordable. But you have to understand the Russian mindset: they are very, very pragmatic and focus on function. No time is spent for adding "beauty" or "nice to have" features that do not improve function. This is why Russian weapon systems cost a fraction of their NATO counterparts and still are deadly for the enemy.

So the Open Source Gerbers were not 100% perfect in the sense of faithfulness to the originals. But they work, all the time, like an AK does. I say this as many of my builders expressed some concern about the functionality of these PCBs. Don't fear: they do work, especially if you order them with the doubled copper weight, which greatly improves the power grid. IMHO this is fault of the original layouter who was more an artist than an engineer. Of course the power grid, which is lacking in performance on all Apple-1 PCBs, including the originals, could be improved a lot by modifiying the layout. But then you lose the correct "looks" compared to the originals. I think this is not desirable. The original "looks" must be preserved. So the best remedy probably would be to go multilayer. With 4 layers, the inner two layers could be used to make super robust power grids over a real ground plane, while the outer two layers would stay the same. Having a ground plane would also greatly improve EMI so the electromagnetic spectrum would not be polluted as badly as the Apple-1 in its original form does. It would never pass FCC tests. Remember, Apple had to redesign the Apple II several times to get it FCC conforming. Because ... the first layout was done by the same guy who also did the Apple-1 (or so I was told).

The upside of having a good, FCC conforming layout with less EMI is not just to satisfy those pesky bureaucrats. Less EMI out also means less EMI in. There is a gadget called an "ESD gun" and a very popular prank is to "fire" that gun in an electronics lab ... oooops. Some systems and some experiments go down and need to be rebooted. If you "fire" an ESD gun in the vicinity of a running Apple-1, it will crash. And with "vicinity" I mean some 3-6 feet distance !

This said, the next possible improvement step would be power and ground grid integrity by adding two inner layers. The cheapskates would still only order 2 layer boards (hopefully with double copper weight, the price difference is negligible) and the quality builders would order the full 4 layer PCB.

So far my suggestions.

But I have a few questions, too:

- Where did you get the information what the differences you corrected are ? From an original Apple-1 ?

- Did you do a manufacturing run to test your new Gerbers ?

Comments invited !

Bernie,

Thank you for your kind words! So, to answer your questions. I have posted a 2 page document that represents all the notes I took and I added that to the publicly released Rev. 1 design files. I have already been working on the Rev. 2 design right now, and Rev. 2 is probably the biggest one, it's also almost done, I might even finish it today or tomorrow. Anyways, everything on those two pages is what I have done to the board/modified since I started... To answer your second question, I probably won't make any PCBs until I have finished doing all the modifications, especially because it would save LOTS of money than making PCBs for each individual revision. I think you had a third question there, and I think it was that you were wondering where I was getting my information from to do the mods, to answer that, all I am doing is taking hundreds of photos off of the Apple-1 Registry and using them as pure reference to make changes to the board. But sometimes there isn't enough photos that cover certain areas of the real boards. I also have a design schematic to match my electrical work to, which I also release the schematic with the publicly released revision files. Also, for anyone concerned about it's functionallity, electrically, nothing is changing on the board, just the artistic beauty of the board is. I believe I will probably have a Rev.3 which will probably be the final revision of the modifications that I do, unless somebody points out a spot that I missed. Since I have started on this task, SO MUCH has changed already and I am really happy with how the board looks even right now. I have made at LEAST 25 modifications in almost every layer of the board, except the outline of the board which just has 7.

I really hope everybody likes my work and how they look, and decides to use them as a standard replica as well.. I wish I was getting paid to do this, but then again I don't care for the money because I love doing this for fun. It makes me happy to make a better looking board for the community. I think I only have one concern about all of the work I am doing and that is that I don't have access to a REAL Apple-1 right now. I might have access to one in the short future. I felt that getting access to a REAL Apple-1 was my only choice of action, because I had previously tried to have someone take high-resolution photos of the real board, but after reading the applefritter user @fingerz 's post a while back about taking even just a single Top view High-Resolution photo of a real Apple-1, that was shut down pretty quick by Achim and Corey. Corey had stated that "Mike Willegal and I have high resolution photos of many of the existing Apple-1 boards, we just do not share them as we do not want to provide additional information which may allow someone to create a replica that is so accurate that at some point there could be a mistake made and it is sold as a real one. Not saying anyone would intentionally do that, but you never know if someone's family member thinks it's real and tries to sell it after someone passes away and an unsuspecting buyer pays big money for it. This happens a lot in the vintage watch community and 9 out of 10 times they are fakes. We just don't want to enable a mistake like that."

Achim had said in Jimmy's @fingerz post that "I got many inquiries about getting high-res pictures and so far it was always to get better replicas. Between replica and counterfeit It is a pretty thin line to cross. The photographer might have the honest reasons to take the pictures. But too many black sheeps are everywhere.

Some people asking me about super-high-res pictures might be the nicest and honest human on the planet, but others are not.If someone asking for pictures of the back and pictures of conducting paths under ICs than sorry, that rings a bell.

To make this clear: I totally understand people wishing to get a nice replica. BUT, if someone telling me he wishes a replica with even correct conducting paths in invisible sections, than NO. There is absolutely no respectable reason for this. There is only one reason for such a request: producing counterfeits.

Even the biggest fan would not notice nor can he/she see what is under the chips.

Any reliable collector or Apple fan will be happy to get a nice replica and will not need a counterfeit."

So that's kind of why I never asked anyone on Applefritter because I feared that they would also shut me down as well from getting them, I have only asked maybe 3 people total about taking photos. If anyone wants to help me get photos, your help is GREATLY appreciated. As for my situation right now, I hope that fellow A1 enthusiasts on Applefritter are willing to help with this project. I would also love to have the support of @corey986 and Achim as well. Also, I will say this, I do understand the hesitancy of why certain photos of the board are not being shared, but I also think that even if those photos were released and it did help creators make better replicas, they could never be passed off as originals because, the way in which the Apple-1 boards were manufactured back then in that Atari Fab, they used a NOW RARE method of applying the soldermask and the silkscreen layers. Also, I don't know if ANYONE has the details of the type of FR4 or the laminates that were used on the boards back then. But until or even IF that info is ever shared. It won't even matter because the FR4 type and probably the laminate material has not been used in almost 46 years. So nobody could ever perfectly match a replica to the real boards no matter how hard anyone trys, but I also say that with enough perserverance someone could probably get a 85%-90% accurate board down the line.

I think a 100% accurate REPLICA of things like the Apple-1 is a WONDERFUL and ethusiastic idea. Not just not achieveable unless you literally time travel back to 1976 and steal a blank PCB of the assembly line. Haha.

Anyways, comments are also highly invited as well. Everyone share your thoughts! I love these conversations so...

Best,

Logan

I don't have a strong opinion on this topic and would not prevent somebody with legitimate access to hi-res photos from sharing them here.

Tom,

Thank you for being willing to allow users to share the photos to Applefritter, that is a great help. Really! I also wonder what your take actually is on this topic by the way?!

Best,

Logan

It's not important to me that hidden traces are perfectly accurate, but I also don't think obscurity is going to offer viable protection against counterfeiting long term.

Very interesting viewpoint! I respect it. I also agree. I think until those photos, if they ever surface, that would leave them recognizeable because those traces wouldn't be perfect. Also since there's a schematic they will for sure be electrically the same.

Best,

Logan

In post #3, Logan wrote:

"Corey had stated that "Mike Willegal and I have high resolution photos of many of the existing Apple-1 boards, we just do not share them as we do not want to provide additional information which may allow someone to create a replica that is so accurate that at some point there could be a mistake made and it is sold as a real one."

Uncle Bernie's opinion on the topic of counterfeit Apple-1:

I do respect the work of Mike Willegal and Corey, but I think their fears are unfounded. There will be no counterfeit Apple-1 which would pass as an original (except for idiots).

If it were possible to make perfect counterfeit Apple-1, you could get them at auction at Bonham's and elsewhere.

I would have have made them in my evil lab and some "expert" would have authenticated them. We would have split the proceeds 50:50. After a few such deals, I would buy the private jet I always wanted and the "expert" would have made 1000 x more dough than he ever could have made with restoring and authenticating Apple-1.

The problem with this dream of mine (some would call it a "nightmare" - fake Apple-1 - yikes !) is that it's not gonna happen.

I am not willing to discuss anything about the insurmountable obstacles I ran into in detail, but believe me that as a semiconductor industry insider I know enough about ICs and PCBs that my opinion about the impossibility of a perfect counterfeit Apple-1 which could stand any useful amount of competent scrutiny using professional methods known in the electronics industry for quality assurance and failure analysis stand on solid ground. It simply can't be done. A few simple industry standard tests and the forgery would be exposed. And other than with certain famous and rare vintage supersportscars you can't buy one and cut it in half to make two identical twins with the same provenance and chassis and engine number (of course "cutting in half" is an over-simplification for a process that takes years and costs a lot of money to pay for true masters of certain crafts, such as skilled tubular frame welders and body panel beaters ).

The critical point is that Apple-1 and all its components were not handcrafted, they were made with industrial processes which are lone gone and dismantled, and the machinery and installations were very expensive. The chemicals used to make the PCBs do not exist anymore. All the compositions have changed a lot. It's not like finding the recipe of the paints used by the old masters - these were hand mixed in a very primitive way. And despite of this, a lot of forgers of famous paintings got caught using modern pigments that did not exist before the 20th Century.

So what is the real motivation behind hiding the hi-res photos ? Well, certain gentlemen have the monopoly for assessing the authenticity of Apple-1 and these photos are part of the process. If the hi-res photos would be out in the wild, anyone with good eyes and a brain could authenticate an Apple-1 to a high degree of confidence and take the "bread and butter" away from said gentlemen.

IMHO, having the hi-res photos out in the wild would do the opposite of what is claimed by these gentlemen. Instead of making forgeries easier, they would make forgeries much, much more difficult because everybody would know which subtle details exist and what to look out for. Looking and comparing is easy if you know how a real one is supposed to look. But reproducing all these little details caused by industrial processes by hand, not having the massive industrial installations available, is all but impossible. You need to rebuild the installations first. Try find a wave soldering machine today which is from the 1970s. Modern wave soldering machines could not do the job. The owner would not allow you to load it with leaded solder and then run experiments to get the exactly same effects on the PCB as seen on the Apple-1 originals. Oh, and you would need to build the chemical factory to make the PCB materials, too. And the factory to make the PCBs. And so on.

I recently saw a video on youtube about a poor guy who, despite he was dealing with electric guitars for years, and pretends to be pretty experienced, was fooled by a forged Gibson Les Paul Slash Snakepit electric guitar:

https://www.youtube.com/watch?v=7u7M3dlr-Qk

Despite an Apple-1 is no electric guitar, if you watch that video you will find out what I mean: Gibson built these guitars using modern industrial fabrication techniques including CNC machines. Whoever the forger was, he did use hand tools instead, and he certainly had no CNC machine. So those who built the real Snakepits knew where to look for and immediately exposed the forgery. There are numerous other small details on the fake guitar which would have been a dead givewaway to the unsuspecting buyer, but alas, he had never seen a real Snakepit with his own eyes. So how could he know the subtle little details to watch out for ?

The same is true for classic collectible sportscars. Once the price exceeds a certain threshold, anything goes, and the forgers and counterfeiters are being attracted like moths are attracted to light. I could tell you stories ! You need to know how a real example looks, smells, feels, and drives to spot the manipulated ones and those built up from wrecks. Even weight can be a giveaway that something is wrong. Some "artists" build up a completely counterfeit car around a salvaged part with the original chassis number. And then, the "make two out of one" con artists.

I can't see that happening with Apple-1 despite of the $1 million price tag. And I saw a lot of weird things in my life !

Comments invited !

I'm not speaking for Corey, but I think it's in poor taste to jest about other people's integrity.

Bernie,

I agree Bernie. I think that was the same point I had, there just simply no way to perfectly make a replica of an Apple-1. It's like you said, they used different manufacturing processes and those processess simply arent used anymore. I sincerly hope that this post brings some light to this topic. Because I really think that the High-Resolution Photos really will help not just the community that is making better replicas, but, again like you said it would help not just Corey but it would help the entire community be able to seek out the differenes in a counterfeit, and I REALLY agree with that.

So, that's why I think doing a project like I am doing is a really good thing.

Best,

Logan

Hi Tom -

I read your post #9. You have a point. But please allow me to clarify:

I did not intend to question anyone's integrity. It's meant just as a hypothetical scenario, a phantasy that can never happen. Maybe it could happen in a parallel universe, who knows. But not on this planet. Alone the wording with the "evil lab" should tell everybody that I'm joking.

But I agree, I may have a terrible taste when it comes to women, bosses, and other human interactions. Some people tend to get my sick jokes into the wrong throat.

Especially the bosses hated me for my humor. Undermining their authority, they said.

So to not hurt your feelings, and being a true Gentleman (harhar, another sick joke of mine) I've edited the wording you took offense in to be gender and race neutral and not mean any specific person. I think the joke is now less funny, and much weaker, and if we were in a circus and I was the clown, nobody would laugh. But the circus director would not snap his whip after me, either.

regards,

Bernie

I am watching this project with great interest and wish mrtitanic777 to achieve his goal. As for the high resolution photos, I don't think they will help you much. By the photos that are on the site Achim all very clear. It is an excellent resource. And we have to say a big thank you to him for this great work. 11 years ago Misha had much less information.

I also want to say that you should not push the owners of the original Apple-1 to do something. It should all be from the heart, but you have to respect their decision and they don't have to explain why they don't do something. This is their personal thing, bought with their honestly earned money and they have the right to decide how much to share.

Translated with www.DeepL.com/Translator (free version)

I think Corey and Mike's fears are not entirely unwarranted.

There are a lot of idiots out there. A lot of idiots with a lot of money. Even if it is virtually impossible to make a fake that would fool UncleBernie, it is possible to make one that would fool most other people.

I know it isn't exactly the same thing, but in the vintage guitar market there are occasional fakes of collectible models like 1950s Fender Stratocasters. Most of these are easy to spot by even semi-experts like myself. However, some very careful craftsman can make and age one to be virtually indistinguishable from a real one. I used to know a guy (now deceased I think) who could build a fake Strat that probably would have fooled Leo Fender himself. He was careful to only make them for himself or people he knew he could trust not to try to pass them off as real. Unfortunately one he made for someone the guy died, and his heirs had no idea it was a fake, so it was sold to one of the high dollar vintage guitar dealers who's "experts" authenticated it as the real McCoy. When it went up for sale my friend found out about it and went to Chicago where the dealer was at. He told them it was a fake, and they didn't believe him... until he showed them pictures of it being made, along with where he had signed it in the neck pocket (real Fenders of that era were signed, but obviously not with my friend's name). They had to withdraw it from the auction they were going to send it to, and there was a big dispute with the heirs about returning it and getting reimbursed.

Another problem is... Even though there are people active NOW that may be able to identify fakes... How many people might know 10, 25 or 50 years from now?

And frankly, I don't want even idiots to get ripped off by paying full price for a repro. Even if the sellers don't know it is a fake, I don't want them to be in the position to sell something and then have a customer get it authenticated by a better expert and have it fail.

Even if it is unlikely, problems are bound to happen sooner or later if there are too many "nearly perfect" repros.

Igor,

I thank you for your support! However I do have to disagree with you on somethings. I believe the High-Resolution photos will REALLY help with 1. public documentation of the entire board, and 2. to help make better replicas EVEN THOUGH we could never perfectly match our replicas to the real Apple-1 boards.

To answer your other statement. I never intended for any miscommunication. I mean't to say that, I will never push any real Apple-1 owner to do anything they don't want to do. I was only saying that out of all the owners, whoever they may be... If they are wanting and willing to help me with this project, I was saying for those people to not hesistate about helping in the nicest way. That's all.

Best,

Logan

@Softwarejanitor

I respectfully agree with your side of the coin, while I am doing this project. I had given some thought about how this would turn out far down the line. The only solution that I was able to use to resolve this problem was to purposefully put a mistake on the board to distinguish at least the replica I MYSELF am working on from the real board, and to not disclose the mistake to anyone. I think this would really help out with that dilema. Especially when it would come to authenticating if the replica is a fake or not.

Best,

Logan

In post #13, softwarejanitor wrote:

"Another problem is... Even though there are people active NOW that may be able to identify fakes... How many people might know 10, 25 or 50 years from now ?"

Uncle Bernie answers:

It's the same with the paintings of the old masters. These paintings were made hundreds of years ago and despite of these many centuries gone by, we still have experts to authenticate them. And the forensic methods to expose forgeries even get better with the progress in techonology we have made. So unless our technological civilisation collapses, which indeed could happen within the timeframe of 10, 25, or 50 years from now, the chances for forgeries to pass as "real" are getting slimmer and slimmer. And if our civilisation collapses and billions of people will starve, fake Apple-1 would be the least of our concerns.

There is a whole, legit, worldwide industry which thrives from producing fine, high quality copies of famous objects of arts, across all fields of artistic endeavor: paintings, sculptures, jewelry, fine mechanical timepieces, designer furniture, for each and every of these sought after objects d'arts there exists some skilled artisan who can make perfect copies – but they always come at a price. For some objects, which originally were made using mass production techniques, such as certain famous designer lamps or pieces of furniture – the work of Charles and Ray Eames comes to mind – there even exist manufacturers today who are using the very same mass production techniques, based on the same blueprints, as the originals. These legit copies typically are made under license from the holders of the copyrights, which often are the heirs (or the foundations) of the original artists. Made to exacting standards and using quality craftsmanship and quality throughout, these modern reproductions of the famous originals are not cheap – but they cost much, much less than the priceless originals seen in museums and the private collections of the rich and famous.

And this industry has long solved the problem of authentication and passing their "clones" as the "originals". They put clues into their products which are invisible to the human eye but can be unveiled by some form of radiation, like ultraviolet light or x-rays. There are perfect reproductions of famous paintings of all periods (even modern ones like Lichtensteins or Warhols) which even an expert could not discern from the originals with his plain eyesight. Many museums and collectors display such perfect reproductions in lieu of the priceless originals, which are stored in some safe and climate controlled room. The museums would never admit that the objects on display for the public are perfect reproductions. But nobody could tell the difference. Even the experts can't. But put such a reproduction in an x-ray machine and you can see the word "REPRODUCTION" - leaded paint or some metal foil which was put on the canvas first, before the secret process to make the reproduction was applied. It is not possible to remove these clues without destroying the whole work.

For the Apple-1, we could do the same. Just add the word "CLONE" somewhere under some IC sockets. In metal traces to see it in the x-ray. If enough of them are hidden everywhere, this would discourage the fraudsters in a big way. If I would have the magic ability to make perfect Apple-1 clones (no I can't do that, as explained before, even to try that feat would cost so much money that buying an original would be cheaper) I would put such clues down hidden everywhere. Even the backside of all ICs would be engraved with "CLONE". The reason: I would want to stay out of jail, stay free, and enjoy the financial rewards of making these reproductions. I'm quite sure I could make six figures per example, at least. There are poor multi-millionaires, too, which can't compete with the billionaires who buy the originals for 1 million US$ each. But as I have explained above in this thread, it can't be done. Not for $100000, not for $250000, not for $1 Million. It's simply too few money to recreate all the industrial installations and all the materials and all the processes. Unlike a painting, the Apple-1 is an industrial high tech product (of its time) with a huge and deep supply chain behind it. No amount of money can recreate that point in the industrial technologies of that time. All gone. And lost forever. It's a "mission impossible".

So I have debunked yet another horror vision. And I have suggested a fair and square remedy to discourage any skullduggery. So we really could go ahead and try to make the perfect reproduction / clone - as far as possible. As I have explained, we will never be able to achieve this goal. But we should at least try. Making clones which every kid can expose as being fake does not help our cause at all. We want museum quality reproductions. As far as I can tell, we are not even close to this lofty goal.

Comments invited !

Bernie,

You most recent comment has MANY great points. I also agree with the fact that you stated about the replica painting industry. I think it is very wise for those companies to put the word "REPRODUCTION" on the painting with leaded paint. Since those companies do that, that would FOREVER SEAL their work from not getting confused with the original paintings. Aslo, I agreed with this statement of yours "For the Apple-1, we could do the same. Just add the word "CLONE" somewhere under some IC sockets. In metal traces to see it in the x-ray. If enough of them are hidden everywhere, this would discourage the fraudsters in a big way. If I would have the magic ability to make perfect Apple-1 clones (no I can't do that, as explained before, even to try that feat would cost so much money that buying an original would be cheaper) I would put such clues down hidden everywhere. Even the backside of all ICs would be engraved with "CLONE". The reason: I would want to stay out of jail, stay free, and enjoy the financial rewards of making these reproductions. I'm quite sure I could make six figures per example, at least. There are poor multi-millionaires, too, which can't compete with the billionaires who buy the originals for 1 million US$ each. But as I explained, it can't be done. Nor for $100000, not for $250000, not for $1 Million. It's simply too few money to recreate all the industrial installations and all the materials and all the processes. Unlike a painting, the Apple-1 is an industrial high tech product (of its time) with a huge and deep supply chain behind it. No amount of money can recreate that point in the industrial technologies of that time. All gone. And lost forever. It's impossible.". I think putting the word "CLONE" underneath a spot where an IC socket would work wonderfully, or like putting the words A, B, & C underneath where an IC socket would go.

Also, for your last statement. I really agreed with that. I believe your right about us not being close to a perfectly accurate replica, and yes we CAN TRY., and my hopes are to be that guy that severely puts us MUCH closer to being severely more accurate. I think striving for a museum quality board is a VERY enthusiastic, excitng, and great goal to go for!! That is now my goal! You've inspired me.

Best,

Logan

What I meant to say was that a high resolution photo will help you see more, but you can't transfer that to the board. In '76 there were no CAD programs, everything was drawn by hand (Uncle Bernie is sure he can tell you more about this process). CAD software won't replicate it all with 100% accuracy.

It's like drawing a copy of a Picasso painting in Photoshop.

Igor,

Yes. In that case, I agree. But it will for sure help for reference when it does come to drawing it in CAD.

Best,

Logan

I wouldn't purposely put a "mistake" so much as a mark identifying it as a replica. What they do for example, for reprint comic books is put a small "R" down in the corner of the pages, signifying it as a reprint.

I respect your opinions UncleBernie, even if I don't necessarly 100% agree with them. Your suggestion of a mark under an IC socket would be a more than adequate solution to make sure that all but the most ignorant of idiots would not get fooled.

As for experts... there are thousands of old master paintings produced over hundreds of years. The Apple 1 was less than 1000 unit production over a period of a couple years at most. The likelyhood of there being nearly as many experts, especially 25 or 50 or more years from now is probably not as big. It makes it more difficult when information needed for future people to become experts like high quality high resolution images of authentic boards and details about the process and material specs needed to authenticate those items are being kept as secret. I agree with Logan that putting that information out would probably do more to prevent people from being fooled by fakes than allowing fakers to rip people off.

@softwarejanitor

Right. I would agree to also put like an "R" or "CLONE" or something to that effect somewhere on the board. I think doing that is a great idea, I think I will probably go with putting the marking underneath a spot where an IC socket would go. At least that way once it is assembled, it won't have any markings that shouldn't be showing and it will look good. Then if anyone ever needs to know if my board is real or not, they could desolder the IC socket and see the markings.

Best,

Logan

In post #21, softwarejanitor wrote:

"The Apple 1 was less than 1000 unit production over a period of a couple years at most."

Uncle Bernie get's the numbers straight:

In his memoirs "iWoz", Woz himself states that "by early 1976 we had sold maybe 150 computers" (first sentence in the Apple II chapter).

In my notes I have a number of 175 which were fully assembled, but I don't know where this came from.

In Walter Isaacson's authorized biography "Steve Jobs" we can find further clues that no more than 200 original Apple-1 PCBs were ever made.

A typical production run, according to both books, was 50. And according to Woz, all where wave soldered by a contract manufacturer, while in "Steve Jobs" we find a story how the house of Steve Jobs' parents was turned into a soldering workshop - which does not make much sense, knowing a contract manufacturer wave soldered the boards, but it's possible that a few difficult parts were hand soldered, such like the J1, J2 connectors or the LM323K, or maybe even the three big blue sprague capacitors. The solder pads of those would have been protected by a heat resistant tape during the wave soldering process (same as with the edge connector).

Normally, a contract manufacturer would have offered to do that, too, but maybe the fledgling Apple Computer Company was too short of cash to pay for that manufacturing step.

About the clones - my own estimate is that prior to the Open Source Gerbers about 600-800 naked Apple-1 clone PCBs had been sold by the usual sources (Mike Willegal, Mike Newton, and Corey Cohen) but after the Open Source Gerbers became available and everybody could order a production run at JLCPCB no numbers could be had anymore, but the total numbers of Apple-1 clone PCB in the wild must be well over 1000 now.

However, I have learned that most buyers of the clone PCBs are not interested in actually building up an Apple-1 clone. Most stay naked and are used as wall hangers.

I estimate that even with the availability of the Open Source Gerbers, only around 100 Apple-1 clones get built every year, most (3 out of 4) using my IC kits.

So there are definitely more Apple-1 clones now in the wild than Apple-1 originals. Much the same situation with some old masters. The genie is out of the bottle. And nobody can get him back into the bottle. There are enough of the Signetics 2519 IC in stock at IC brokers worldwide to build 5000+ more clones. Oh, and if you give me $250000, I could design a new mask set and produce clones of that 2519, too. But nobody could get the grey mold compound of the original Signetics packages back. All other ICs are still available in abundance, but none with the correct date codes and the correct manufacturers: what the two Steves did not use up, the distributor they bought them from (Cramer Electronics) sold to other customers. So their stock of these ICs is long gone.

All this means that despite we can make lots of clones, just a glance on the IC date codes would expose a clone to be a clone. And we just had a hot discussion about the pros and cons of truly faithful reproductions of the naked PCBs. One of the longest threads I have seen in his forum for a long while. So "hot" ist the topic !

As macintosh_nik has correctly observed in his post #18:

"In '76 there were no CAD programs, everything was drawn by hand (Uncle Bernie is sure he can tell you more about this process). CAD software won't replicate it all with 100% accuracy".

"It's like drawing a copy of a Picasso painting in Photoshop".

The last sentence is brilliant. This is a good metaphor showing how impossible it really is.

When you make PCBs layouts using the old school method, all the traces are not drawn, they are glued on a mylar foil using a self adhesive black, opaque, tape which was specially made for that purpose. So every bend of the traces has a different radius. The same company also made sheets of translucent foil with the footprints of ICs, which could be peeled off and they were self adhesive to be glued onto the mylar, too. You had only one chance to get the positioning right. Otherwise you had to peel it off and get a new sticker. But every IC footprint and every via and every pad for a component was placed manually, and so there are slight deviations from the ideal raster. All this was typically done at a larger scale and then it was photographically reduced at the PCB manufacturer to make the master films for the exposure of the PCBs.

The CNC drill tape also was done manually, with a primitive X-Y digitizer over a light table and a technician manually positioning a probe tip over the "hole" of each pad and then pressing a button to capture the coordinates (typically, on paper tape). This paper tape was then put into the CNC drilling machine and a test PCB was drilled (no traces, just holes). Which was then used to verify that all drill holes were there and of the right diameter by comparing it to the master films.

There was a lot of manual work involved in this process and so making PCBs was not exactly cheap back in the day. The first two or three prototype PCBs cost a fortune as all the prep work was billed with them. I remember even in the mid 1980s this tedious manual process was still in use throughout the industry, because only the large corporations could afford the early PCB CAD programs and the computers to run them (i.e. VAX). Small companies used the tape and glue method well until the late 1980s, when PC based PCB CAD programs finally became affordable. It's not that PCB CAD had not existed - Gerber files had been around since the 1960s and they were used in the photo plotters made by Gerber Systems. But these early machines were very limited - all the shapes like pads were made with mechanical apertures and only the traces were "drawn" by the plotter mechanism. And they were heinously expensive. Only the larger PCB manufacturers had them.

The original Apple-1 PCBs were made with the manual hand glued / sticky tape layout process. You can see the small irregularities caused by the manual process everywhere, especially in the "routing rivers". Just look how these traces don't run really straight and are wiggly.

As macintosh_nik has correctly observed, there is no way to reproduce that with a normal CAD program. But this should not discourage Logan from improving the Gerbers to make them more faithful to the originals. Unless some crazy billionaire will spend the money to restart the manufacture of all these sticky tapes and mylar foils (they had a very fine raster on it, invisible to the repro camera) it's impossible to to any manual PCB layout anymore, sorry.

Again, yet another lost art.

In post #22, mrtitanic777 wrote:

"Then if anyone ever needs to know if my board is real or not, they could desolder the IC socket and see the markings."

Uncle Bernie laughs:

Oh no, before the fraud is exposed, it's a priceless original ! Nobody would allow the desoldering of an IC socket to verify authenticity.

Instead, take the PCB to any contract manufacturer who populates modern PCBs. They have x-ray machines specifically made for the quality inspection of modern PCBs. The BGA packages, for instance, are notorious to have the occasional ball not being properly soldered, so each and every board needs to be x-rayed to check the integrity of all these critical solder joints.

Other than ESD precautions (bring the PCB in an ESD bag, the workstation has its own ESD straps etc.) all you need to tell them is to use the lowest possible x-ray energy and dose where they can still see the traces below the IC sockets. And you tell them to watch for the "CLONE" or "REPRO" or whatever hint could be there and snap photos. And then you have proof !

The problem with the x-ray energy and dose is that modern PCBs may have a huge number of layers and so the operators dial up x-ray energy and dose to see the solder balls. This radiation dose may damage ICs (and then the OEM complains about shoddy IC quality at the semiconductor manufacturer, this is how I know it). With a low energy / dose needed for primitive 2 layer PCBs there is no such risk. If you really want to play it safe, remove all the MOS ICs (using ESD safe workplace). The TTLs under which the "REPRO" clues are also should be removed as the leadframe of the IC will block the x-rays, too, and despite the text still would appear in the gaps of the leadframe, it's always better to get all the obstacles out of the way.

Comments invited !

Bernie,

How about putting a "1" in the jumper area?

3D3B4707-1016-4FEC-8D94-A59CD2166110.jpeg

Best,

Logan

Unless or until pcb reproductions get substantially more convincing, I wouldn't worry about it.

Good discussion here folks.

I don't believe it is possible to make an "original copy" of an Apple 1 due to the reasons already outlined in this thread, though I do believe you can make one that is close.

Like anything in this world, the value of such is the responsibility of the buyer. The original Apple 1 boards are in a registry now, traceable through specific owners and verifiable from fakes.

EVERYONE who builds an Apple 1 replica wants it to be as close to an original as possible EXCEPT of course, those who own an original. I get the reasons why original owners don't want a lot of close fakes out there, but putting obvious clues on the board only detract from those who want to build one "like an original".

I bought a replica board produced by Corey who (at the time) advertised it to be a close match to an original Apple 1 board, but IMO the board didn't pass the "10-foot" test. The size was wrong, the PCB color was wrong and the PCB material itself looked nothing like a board from that time period. The quality of the board was OK and the integrity of the traces were fine and it would have produced a working model of an Apple 1, but I couldn't use my time-period components on it because it looked like an obvious reproduction -even at a distance. Nothing against Corey, he was offering bare boards at a time when getting them was difficult. I understand him wanting to protect the integrity of his original, but hand soldering a board now is an obvious clue. Wave soldering boards is now a lost art. (I used to do that in the late 1970's when Bernie was a young man. :-D ) I could tell you horror stories of that process that would give OSHA nightmares! =:-O

The Apple 1 boards released and sold by Mike Willegal several years back seemed to be the most accurate IMO. Not perfect, but pretty darn close. Mike inconspicuously put his name with a smiley face on the back of all the boards he reproduced, and this made for easy identification. You really had to look for it to notice, and IMHO was a good way to identify the board as a copy.

Logan, if you are going to pursue the the creation of a better board, I would say by all means go for it. I wouldn't put extra numbers, etc on the boards to identify it as a copy, but putting your initials on the backside of the board in thin tiny letters would be good enough. Same concept as what Mike Willegal did. If you do build a new board, BE SURE TO USE GOLD-PLATED FINGERS on the edge connector. I think that is important. Boards you see on FleaBay don't have gold plated edge connections and are undesirable IMO. People will spend the extra $$ to get a board with gold plated fingers. If you run into issues with cost of a run of boards, talk with me off line.

Isn't that what Corey's selling?

In post #26, macnoyd wrote:

"EVERYONE who builds an Apple 1 replica wants it to be as close to an original as possible EXCEPT of course, those who own an original."

Uncle Bernie agrees with macnoyd.

As I sell these IC kits, and coach the builders, I know a lot about their desires. It seems nobody wants to make a forgery to defraud unsuspecting buyers (they never ask for specific little details on how to do that and of course everybody uses hand soldering). But everyone asks which is the most faithful reproduction PCB. Every. single. one.

For this reason I've spent a lot of words on my "Tips & Tricks" pdf which PCB is the best. Since Mike Willegal's / Corey's are not accessible to me, I can't do a fair comparision, but so far I have recommended Mike Newton's PCBs which were of good quality, had real gold plated fingers, and the "non-NTI" version had a nice dull, dark green solder mask which looked aged (but not necessarily close to an original - 40+ years can change soldermasks a lot). Alas, Mike Newton was hit by the cheap Open Source Gerber based ones and this will also affect Corey. Mike Newton is now selling off his last NTI PCBs with minor cosmetic defects at a slightly discounted price and this could be the end of that source, I don't know. I found out that the Russian PCBs are a bit smaller in height (they are 9" x 15.5") than the Newton (which are 9.3" x 15.5") so every cabinet / enclosure maker runs into problems with the mounting hole positions being different.

Maybe this is the dimensions / size discrepancy mentioned by macnoyd. I don't know which is the correct size, as I don't have an original Apple-1. If I had one, it would morph into a nice Cessna 500 Citation I SP. Ten times more expensive per flight hour than the airplanes I fly now, but a good fast getaway plane if SHTF. Colorado Springs with NORAD and the Peterson Air Force base is a primary target, you know.

Anyways, Logan, don't give up ! And disregard the naysayers. I would not put any anti forgery clues on the component side. And as macnoyd has mentioned, a little logo on the solder side is probably enough. Although there will be no huge market for your improved boards - you won't get rich - it is certainly worth doing and it will be a nice side hustle for you for years to come, if you sell these PCBs at a reasonable price. And if you need an investor other than macnoyd, I' also willing to become a venture capitalist for you. Send me a PM for terms and conditions.

best regards,

Bernie

P.S. macnoyd is right that wave soldering machines don't exist anymore. The new ones use a sort of solder fountain ridge spanning the whole PCB width, to solder hybrid populated PCB which have both smd and leaded components. All plain SMD PCBs are reflow soldered and there is no solder fountain anywhere in that machine, it's all in the screen printed solder paste. With the real wave soldering machines gone there is no way to fake an Apple-1 original anyways. A crazy billionaire could finance to build a new wave soldering machine based on 1970s blueprints, but it's also a craft, a skill, to operate these machines, and these people who knew the tricks how to make it work are very old now and soon will be gone. We have lost so many craftsman skills in the last century that IMHO it's a catastrophy. These skills can't be found in books, understand. They were passed on from a master craftsman to their most capable apprentices by word of mouth (and training on the job). And they had to swear an oath to never disclose the secrets to anyone except much later, when they became master craftsmen themselves, only to their most capable apprentices. The medieval guilds kept an eye on it that these rules were observed. These are the origins of the "Trade Secret" laws we have today, codified. Nobody can make a good skythe blade anymore, for instance. So how can the survivors of the collapse even feed themselves ? Oh, and they would not be able to make one lousy transistor either.

Hi everybody,

Quickly jumping in here regarding the "fear of fakes". I, too, think this is totally unfounded. It's a complete NON-issue. You can not make an Apple-1 that would withstand any test procedure no matter how carelessly done. And as originals sell 500k and above, EVERY auction house will make sure a board would be properly tested. In my book, there is no doubt about that. An Apple-1 counterfeit can not be done.

One of the experts accused me of helping fraudsters with my recreations of the Apple-1 manuals. I told him that this was total nonsense as a blind person could tell the difference between my replicas and an original. Why? Because "my" replicas are a computer typeset job, the schematics drawn with the computer, too, not hand. Although these replicas are super true to the original, they will never be usable as a blueprint for counterfeits. Why? Because they look too good, too crisp, especially the schematics – like, even better than the original. it is super easy to tell them apart from the real thing.

But that's not even the showstopper: What that expert totally failed to understand: If somebody really wanted to counterfeit the original manuals – simply scanning an original would be far easier and more true to the original type my re-typeset jobbie.

Apple Germany actually exactly did that in the 80ies. For a developers conference they re-printed the Operation Manual. A colorhouse scanned the original manual and then it got reprinted. They did an awesome job there and I have a copy of that reprint (but I think they fucked up the order of the schematics in that reprint i.e. the front and back of the fold-out schematics is the wrong way round).

Thought I add this – sorry for the diversion.

Best

Armin

Macnoyd:

I also agree that we could make a CLOSE replica for the Apple-1, and yes, it is indeed worth buying in the eyes of the beholder. I am surprised that you weren't satisfied with the Mimeo-1 board. However I also do agree with you about the PCB Soldermask color being wrong, and the dimensions being wrong. Wave soldering is indeed a lost art nowadays. I will probably put something on the board if anyone complains about it not having any distinctions after PCBs are ready to be made, but yes I do agree to add my initals somewhere on the board. I would for sure love to do the gold plated fingers for the edge connector!

Wow! Thank you for the support Macnoyd, I really needed to read that. It truly puts a big smile on my face to have support in this. I think having that kind of help & support is the best thing I could have ever wanted in a project like this one. Again, it really does make me happy! Like a kid that got that christmas present he wanted all year long! Haha.

Best,

Logan

Bernie,

That's good that all your customers do care about which PCB is the most faithful to the Apple-1! I also haven't gotten an Mimeo-1 to compare with. I do REALLY like the Newton boards, my personal opinion is that the Newton Non NTI, & NTI boards are the closest to the Apple-1 PCBs! They look asthetically pleasing and, the traces are actually curved the right direction on many areas of the board, also it has the GOLD plated edge connector.

When you stated: "Mike Newton is now selling off his last NTI PCBs with minor cosmetic defects at a slightly discounted price and this could be the end of that source, I don't know. " That actually gave me a really great idea, I decided to ask Mike Newton about aquring the Newton board design and sales, abd I sent him an email stating:

"Mike,

I think your boards are WAY better than what’s out there. I’ve never seen a blank Mimeo so I can’t compare it to yours but I really like your NTI board, I have touched a Non-NTI board yet.

Thank you for saying that about my work! (He saw my facebook post about my work on the russian PCB & congratulated me.)

I actually might have a proposal for you if you need time to think it over, I was thinking a few days ago about you maybe appointing me to sell/make Newton boards in the future, because I REALLY like your boards. I was also thinking that because some people kept saying that you were finished and selling off your last stock of them.

Hopefully it’s something your interested in discussing?!

Best,

Logan"

Also, when you stated: "I found out that the Russian PCBs are a bit smaller in height (they are 9" x 15.5") than the Newton (which are 9.3" x 15.5") so every cabinet / enclosure maker runs into problems with the mounting hole positions being different." I also thought about how true that was too. I still haven't recieved a response from Mike about the reasons why his PCB is larger than the actual Apple-1 because the ACTUAL APPLE-1 BOARD SIZE IS 9 X 15.5. Also bernie, I want to give a BIG thank you for wanting to be an investor and put forward some money into the project and help me with the manufacturing costs! This also puts a large smile on my face! So thank you fot that & your words of affirmation!!

Best,

Logan

Armin,

I also agree with your statement about the fear of fakes, and I too think it is unfounded, because it's like you said: "You can not make an Apple-1 that would withstand any test procedure no matter how carelessly done. And as originals sell 500k and above, EVERY auction house will make sure a board would be properly tested." That's why I don't get the hesitance. Sorry to hear that an expert said that towards you about your AMAZING work! I truly love your manuals, they're perfect in everyway, I mean you just really did a REALLY outstanding job on those. I find that funny that your manuals are even better than the originals and yet the "expert" still didn't take that into account. Haha.

That is a really cool fact. I didn't know that Apple Germany had done that for their manual.

Best,

Logan