Soldering a mainboard can become a frustrating and

horrible task if some tips are not performed and the results

might even leed up to a

nonfunctional mainboard. If the mainboard is not assembled in a

professional factory with wavesoldering bath then there are

several

problems to handle in the most important one is that you would need a few

hands more than you can offer.

But there is a simple solution : working with the "Sandwich" - method.

the assembly is split to several different stages - depending to the

"hight" of the components....

in general a Mimeo boards for example will be split to the following

groups / steps:

1) resistors

2) sockets

3) filter capacitors and ceramic capacitors

4) small electrolytic capacitors and crystal

5) edgeconnector

6) transistors

7 ) voltage ICīs and connectors

8) finally the big electrolytic capacitors and the volatgeregulator

with the cooling sink

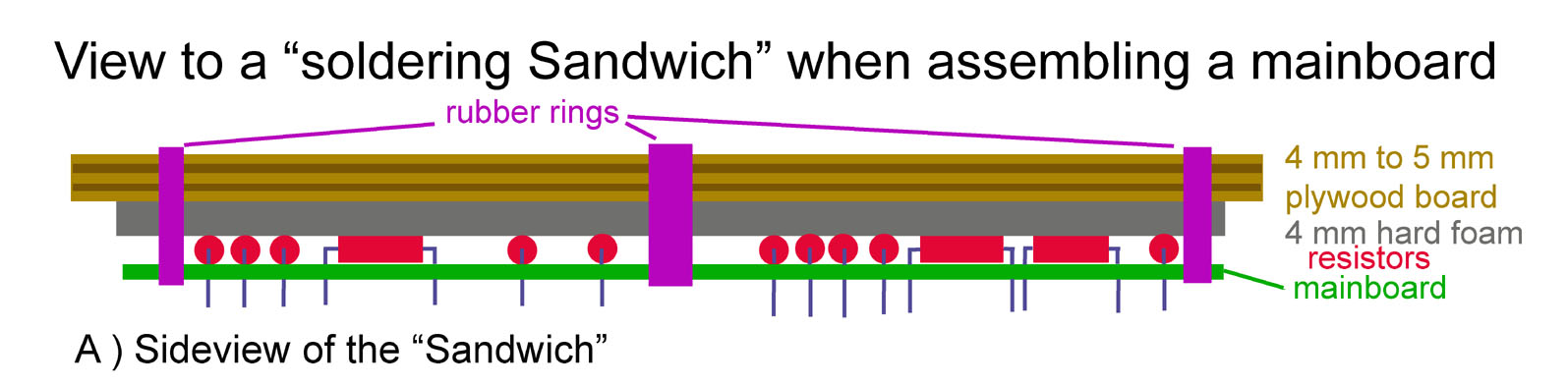

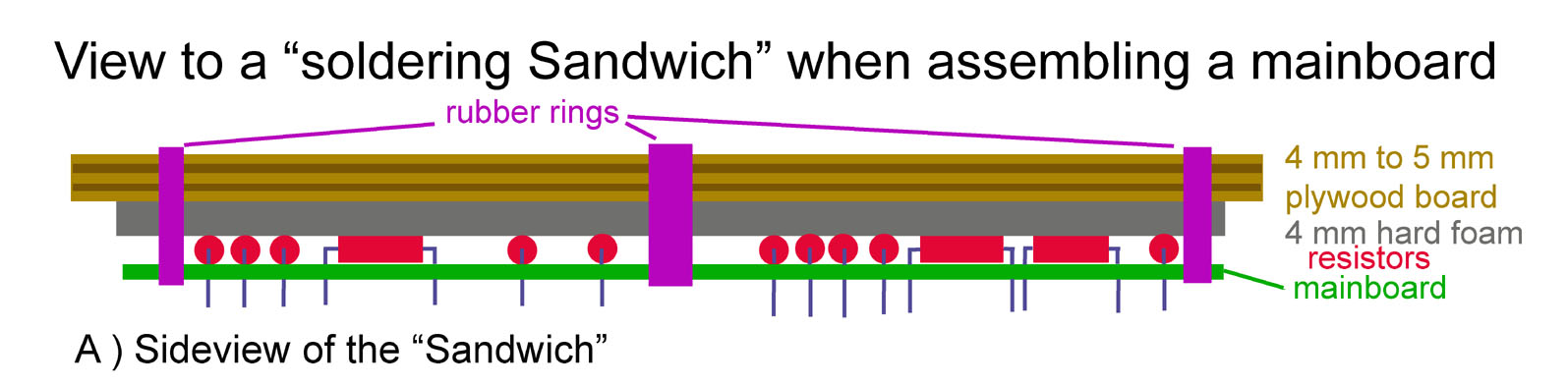

First of all you will need to get a peice of stabile plywood with about 4

mm or 5 mm thickness and the size should be only little bit

larger than

the Mimeo mainboard itself ( there should be a border of 1 cm more at each

side of the mainboard ). That board should be very stiff !

You should not be able to bend it ! This plywood board should then be

covered completely at one side with a rather hard ( only little

flexibel )

foam that is not to weak against heat ( no styrofoam !) by fixing it to

the wood with sheets of doubleside- adhesive tape.

In the first step all resistors are inserted in the board and then the

plywood board is placed on the top above the resistors and then

that plywood board is

fixed with large and strong rubber rings like shown in the drawing below.

| |

|

When the "Sandwich" is complete

and the rubber rings are strong enough, then you can flip that

entire "package" around and start to solder the resistors.

After that Task has been completed you can flip back the package and

remove the rubber rings. You may then start equipping the

mainboard with all sockets

and then you may prepare the "Sandwich" same way as before and fix the

package again with the rubber rings.

Tip: If you first only solder one side of the

resistors so that they keep in position then you may start

cutting the remaining unsoldered wires that way, that

the rest of wire

just keeps about 1 mm above the surface of the board and then

solder that remaining points. Then you can cut the remaining

soldered

wires as short as

possible.

| |

|

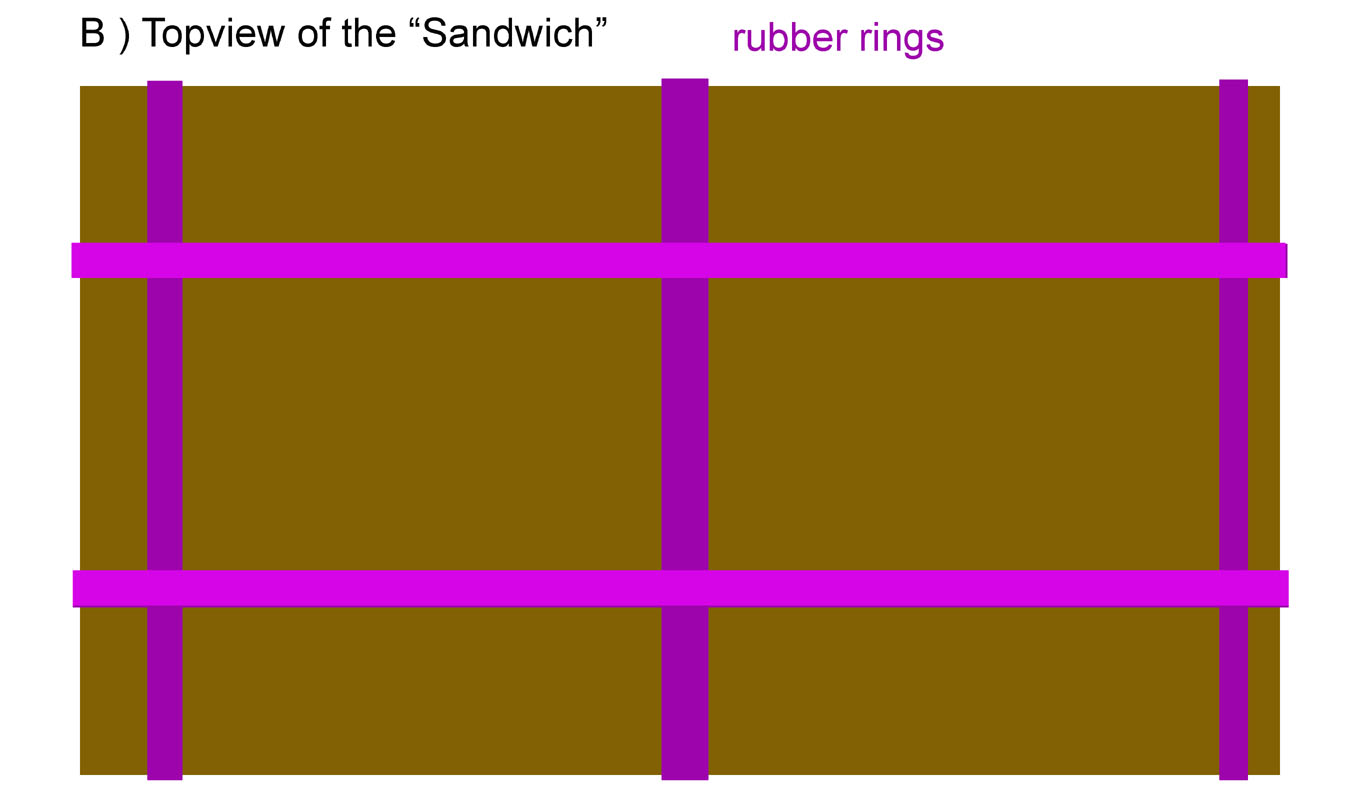

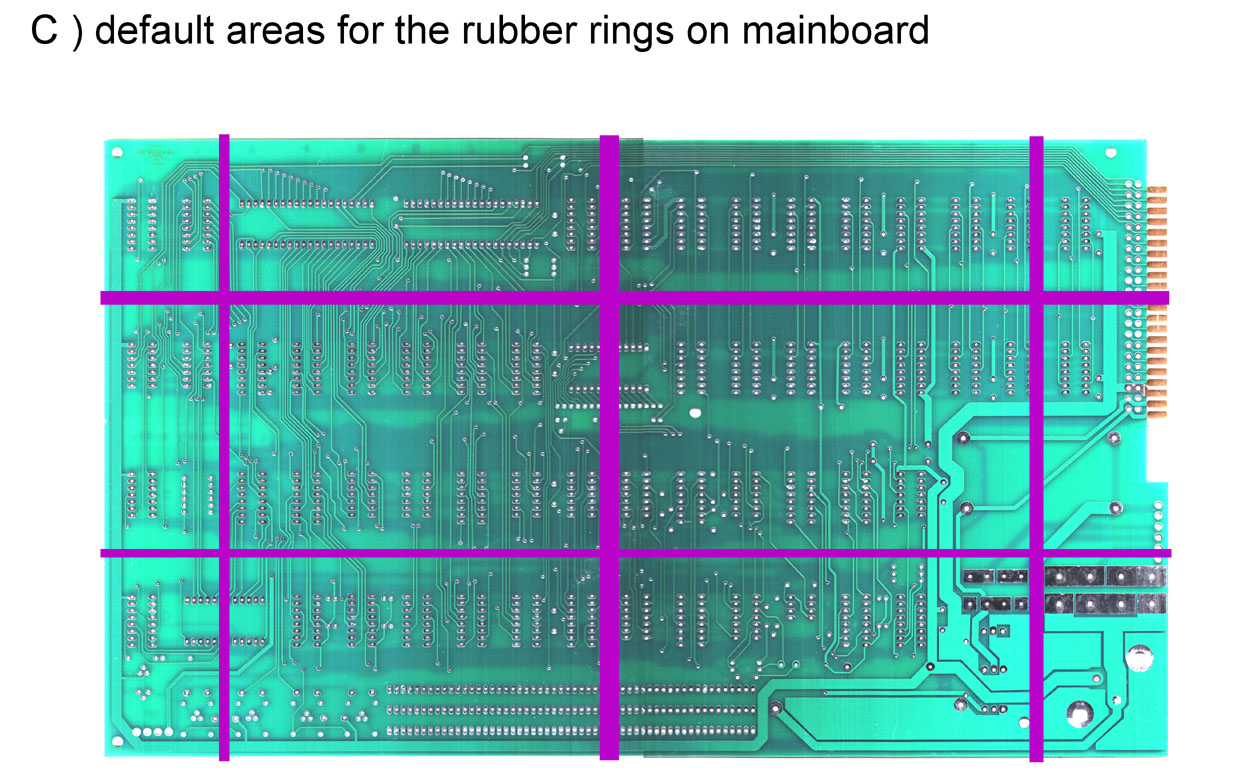

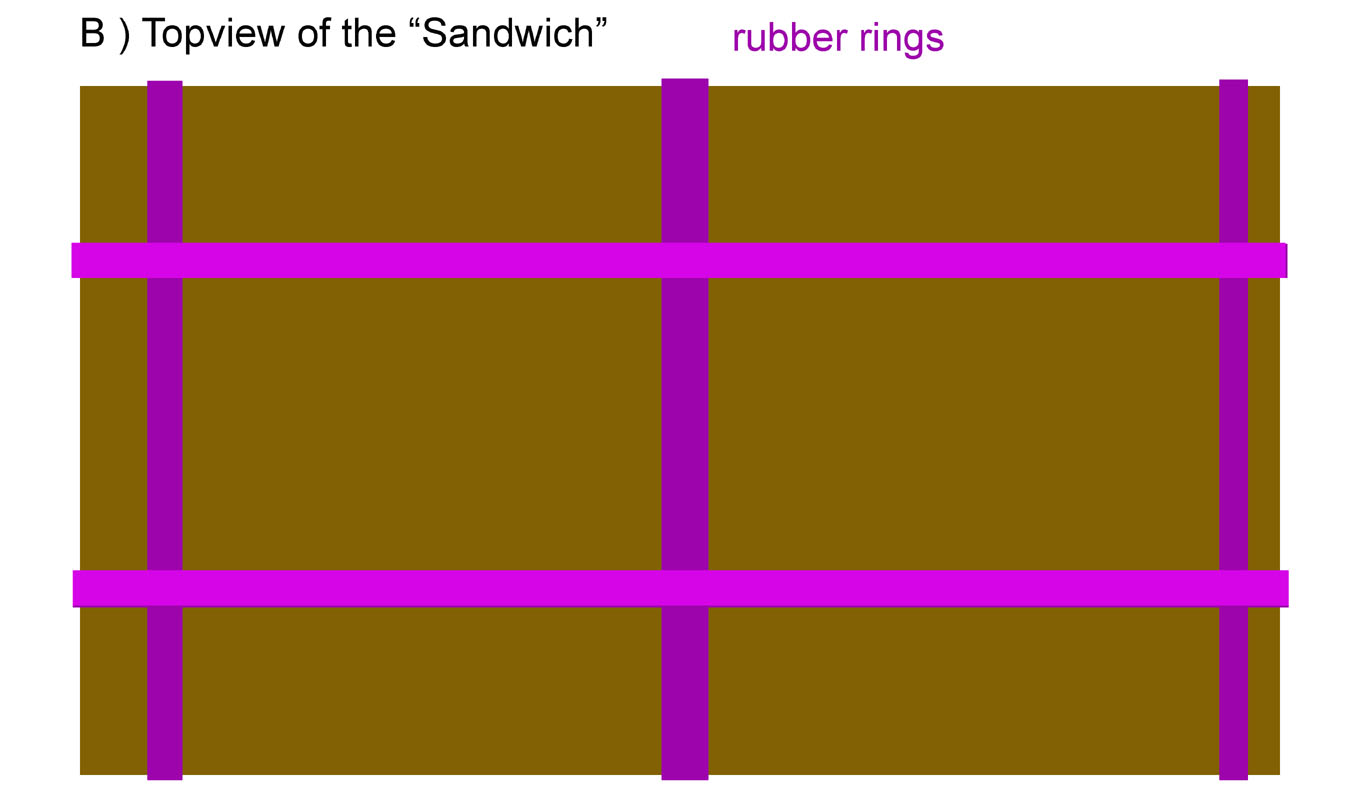

The rubber rings should be

positioned like displayed in the picture above to make sure that

the pressure of the rings is supplied equaly to the entire

surface

of the mainboard at the other side of the package.

That also is corresponding to the areas at the mainboard where nearly no

soldering points are used.

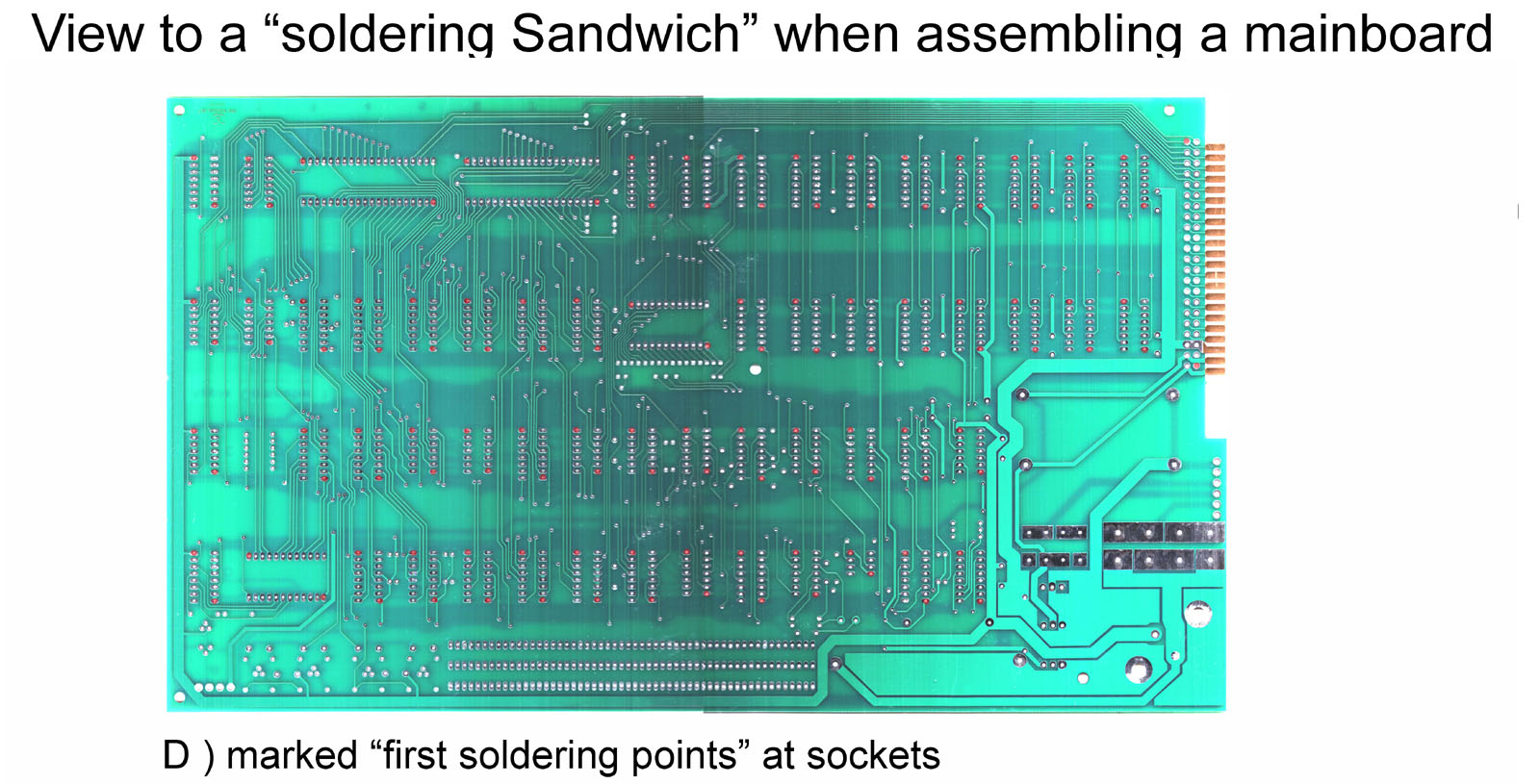

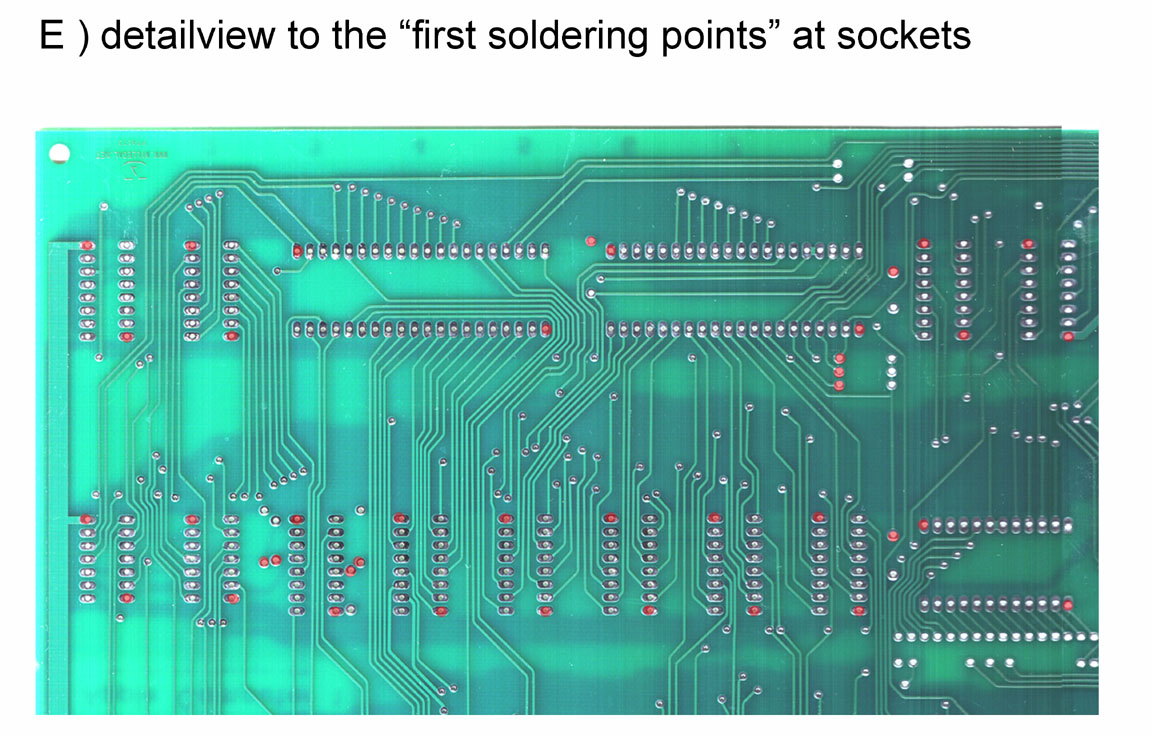

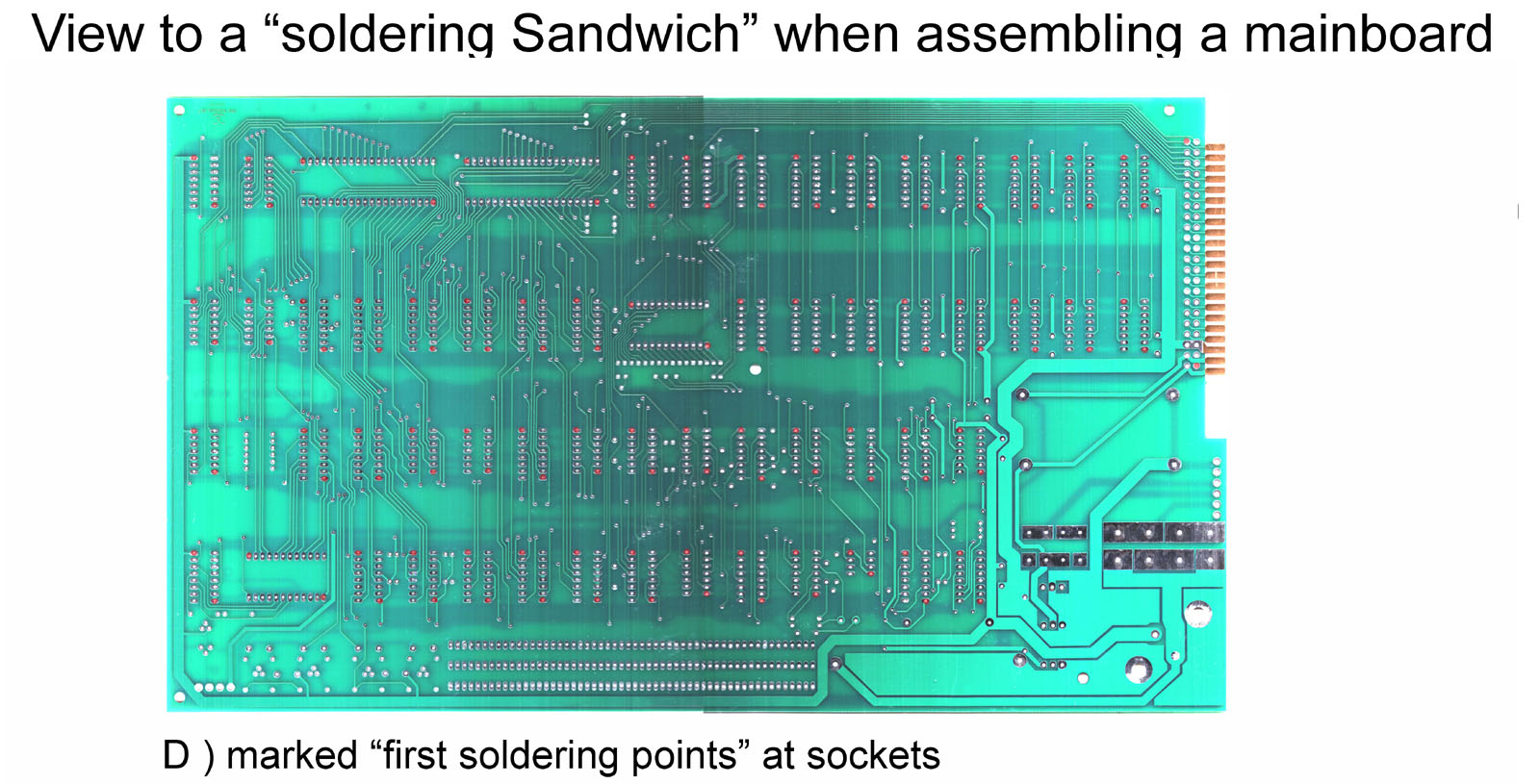

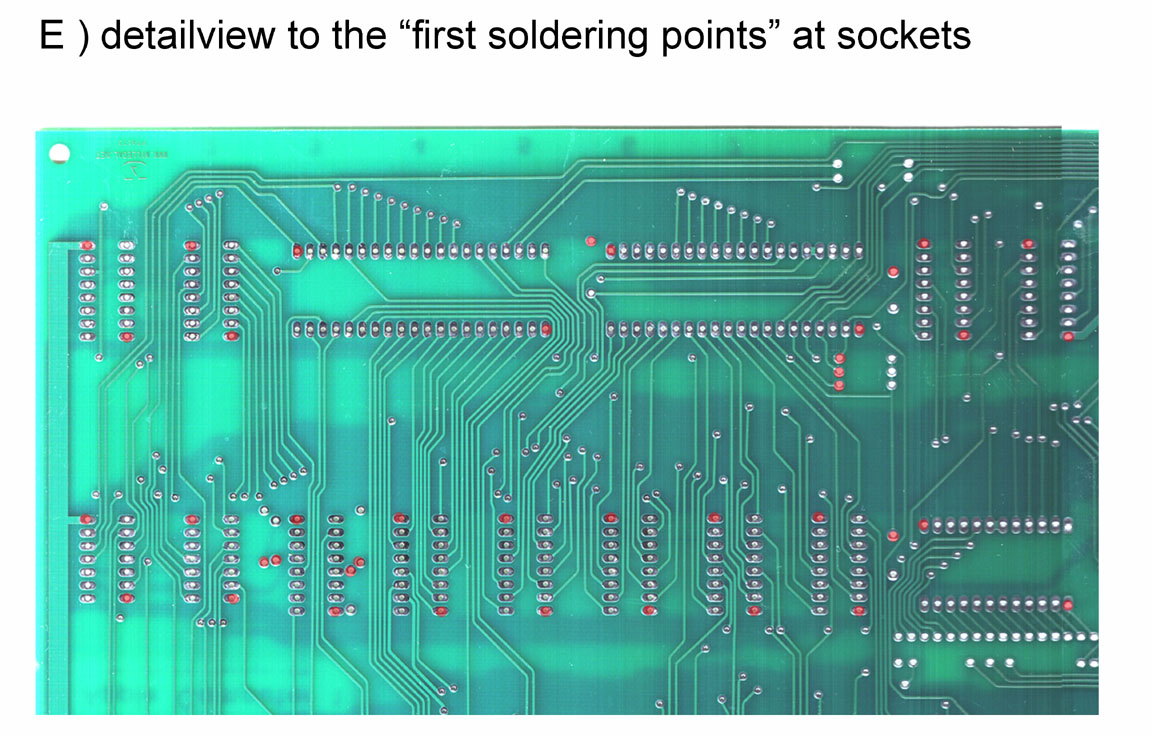

When the "Sandwich" is prepared with the sockets you may flip the package

again to prepare the soldering task

But you should not solder the entire socket at the moment ! Itīs better to

only solder 2 pins of the opposing edges like marked in

the 2 pictures below

( the second one id only a detail of the picture above ).

| |

|

| |

|

After all sockets have been fixed

at 2 points you may remove the rubber rings and the

plywoodboard. Then you should heat again the soldering joints

with the solderingiron each single after another while pressing the socket

with a fintertip at the other side down to the mainboard. This will ensure that

the socket will

slip down the very last few parts of a millimeter in their final position.

After all joints have been readjusted you may solder all the

remaining unsoldered

points of the sockets.

After the task with the sockets is completed the same procedure is

repeated again as listed above with the next "higher"

components.

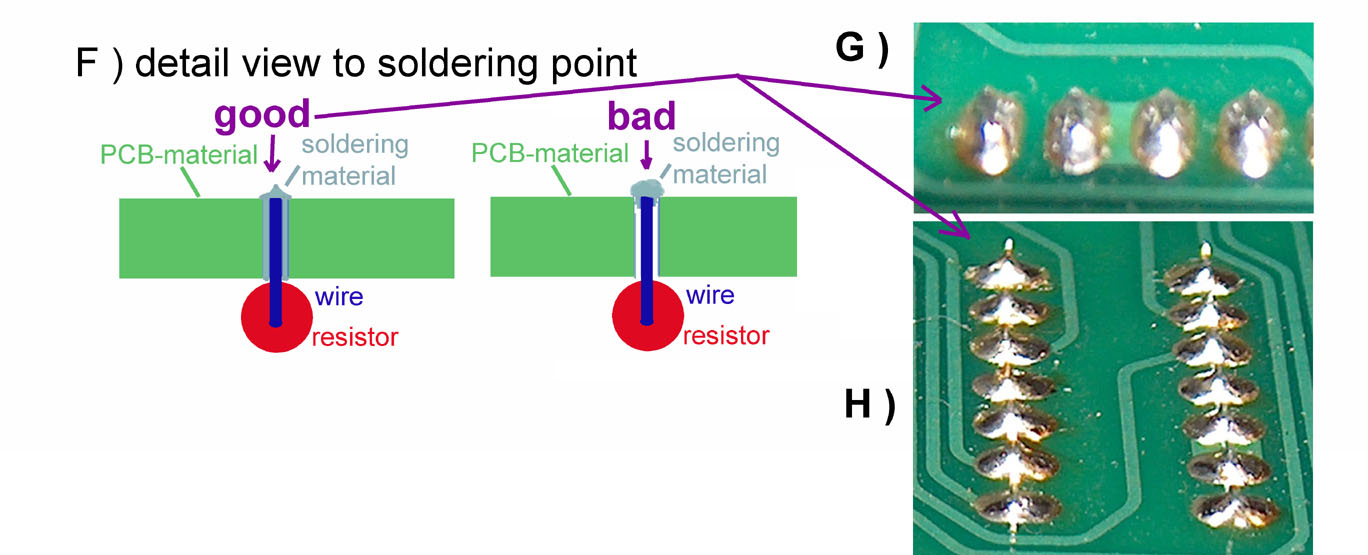

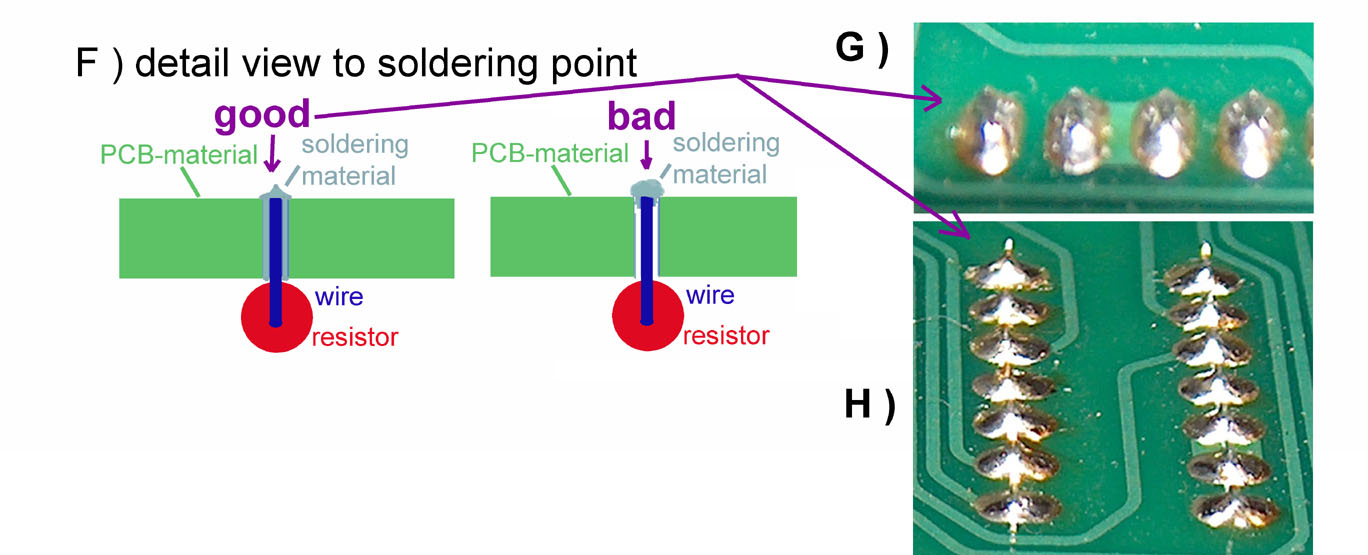

The next pictures examine details related to "good" and "bad" soldering

joints. But before we examine that pictures, it is very

important to

remind, that the results of soldering are also dependent to the quality

of the used tools. You wonīt get good results with bad tools

and bad

soldering material. This is upmost valid, if you want to solder an entire

mainboard ! In such a case it is mandatory the you must use a

soldering

iron with temperature regulation. The tip of a soldering iron

without temperature regulation is completely oxidated after some

50 to 60 soldering joints

and the oxidated particals on the tip cause bad effects to the

solderingmaterial. It will oxidate faster and the flux of the

material gets worser the more

the tip is oxidated. Using a soldering iron with partialy ceramic tip and

regulation fixed to 300 to 350 degrees celsius makes sure that

the solderingmaterial

has best flux and the tip canīt oxidate at that temperature.

Donīt use e large soldering tip ! The correct tip is the one salled in

general as "pencil tip" and it comparable to the size of a

normal pencil.

The soldering unit should be able to deliver regulated power from 15 Watt

to 50 Watt and it should be able to be regulated from 250

degrees celsius

till up to 450 degrees celsius. The optimal soldering temperature is

between 340 degrees and 360 degrees celsius and the soldering

material shold

have a diameter from 0,4 mm to maximum of 1 mm. Using thicker material

causes danger of applying to much material to the soldering

area.

The pictures

below show the difference by displaying how a good soldering

joint should look alike.

The picture of the bad soldering joint shows 2 points: the soldering

material was too cold and did not get really good flux and

therefor it also could not "creep"

into the hole and float entirely around the wire. The picture H) displays

very well a perfect joint: the joint looks similar to the

profile of a "volcano".

In a later step the remaining part of the socket pins above the soldering

material are cut off with a good and sharp wirecutter.

|

|

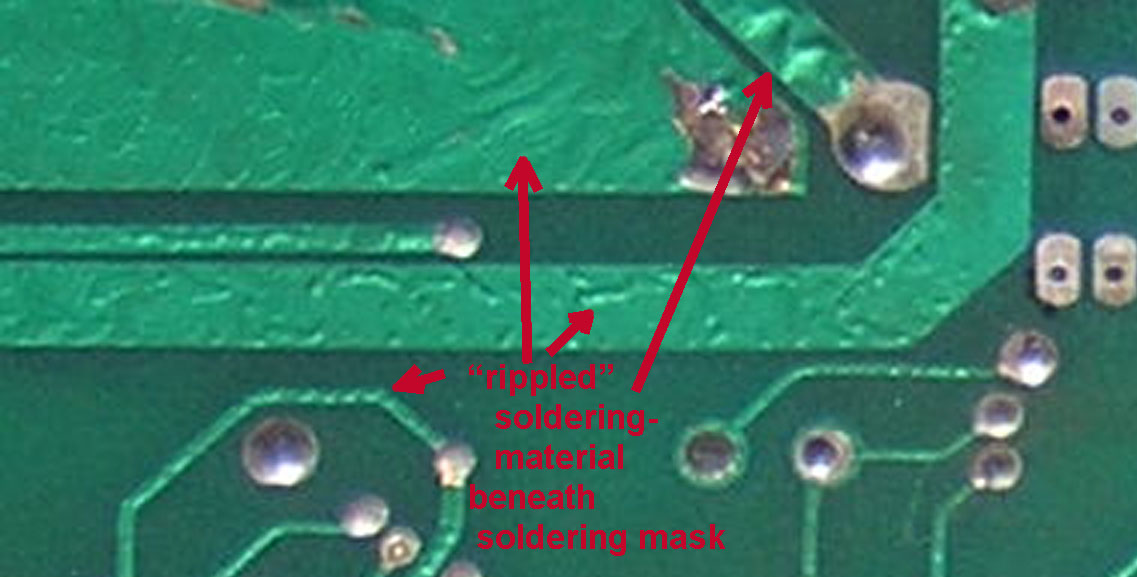

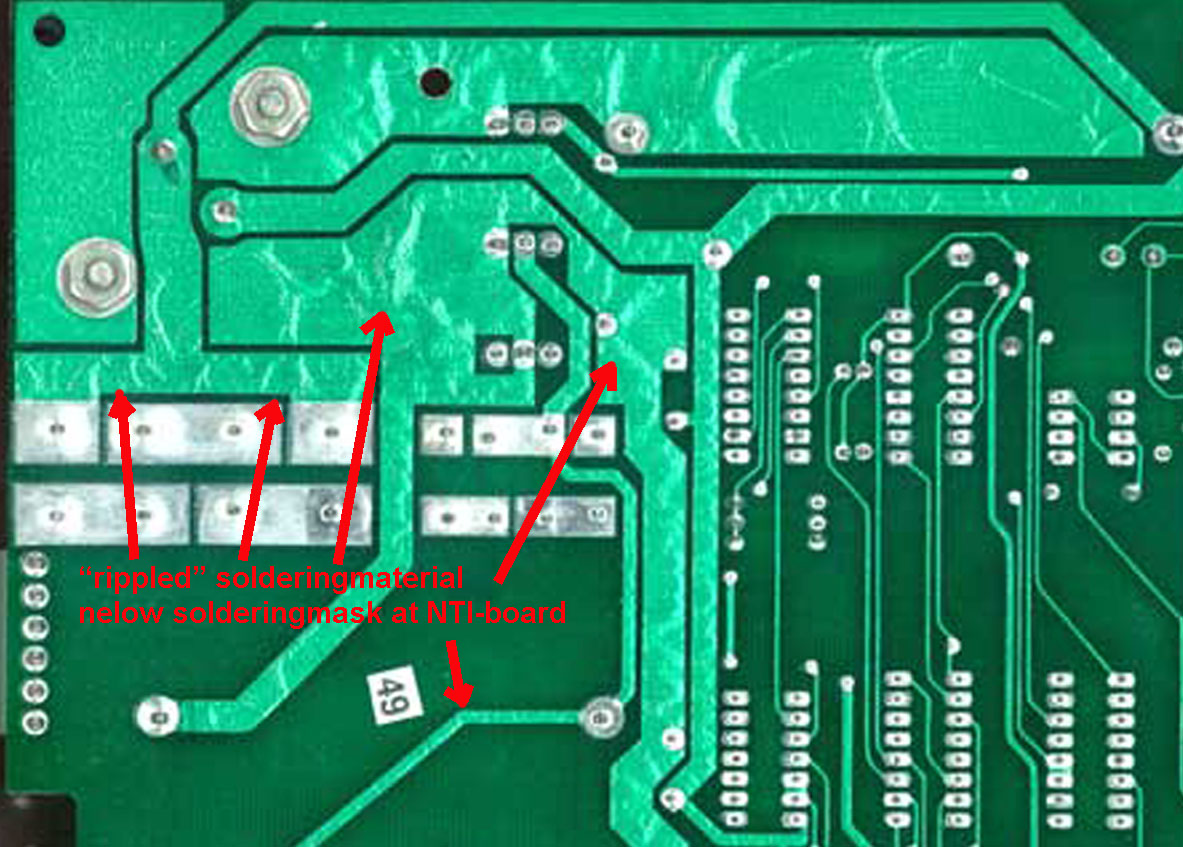

At Applefritter the member

PhilPower mentioned correctly that nobody will be able to

reproduce perfectly the solderingside of an Apple 1 and this is

the best statement to be

given about the topic. This has mechanical reasons due to the fact that

the original board had been wavesoldered. i will display this

with some few detail pictures:

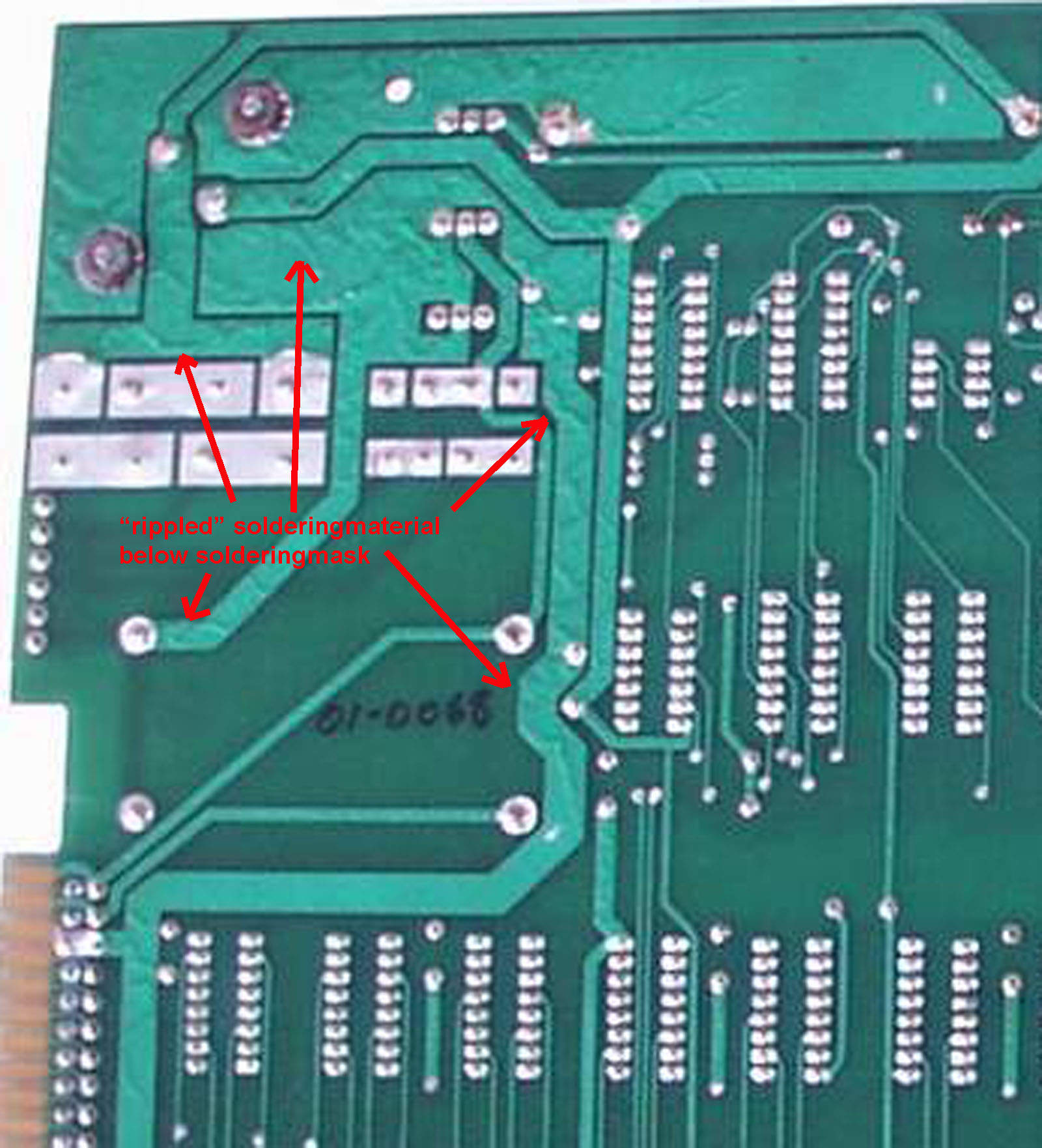

| |

The

pictures above have been from "pre NTI" version

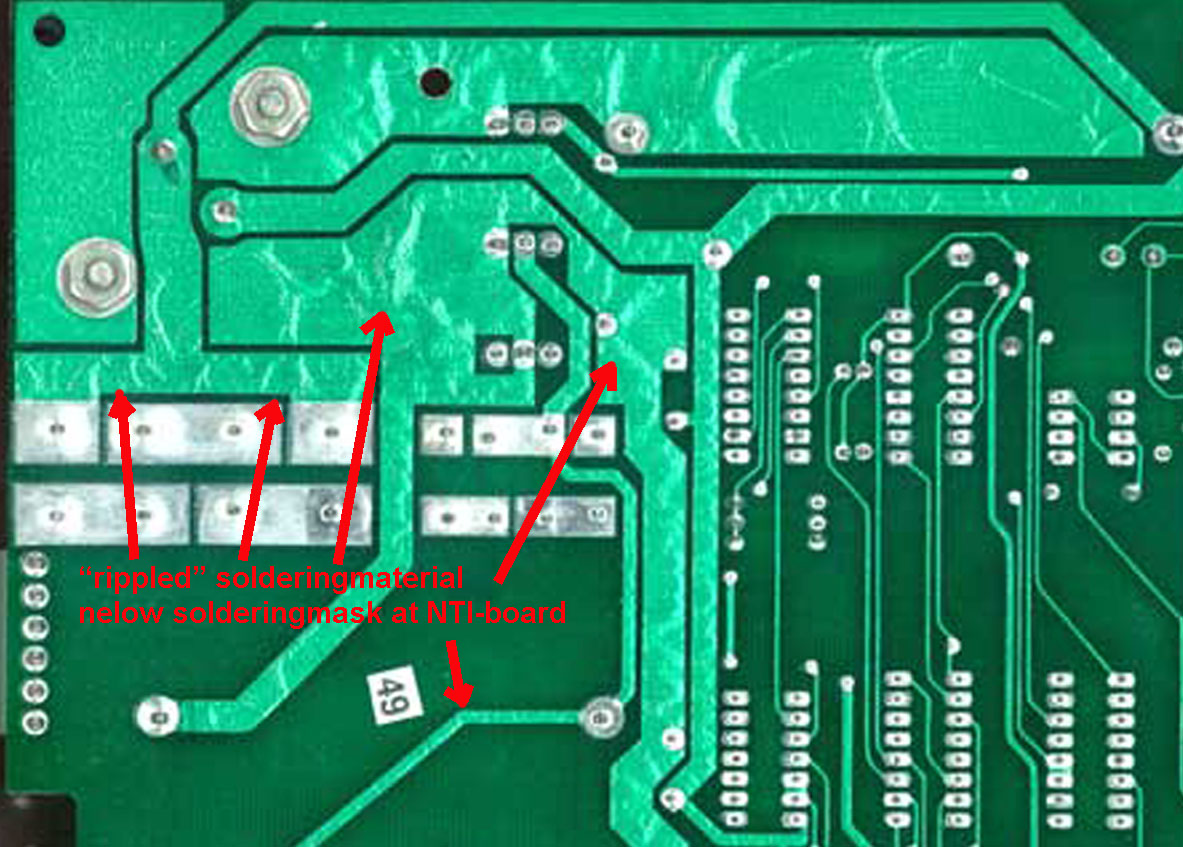

of the Apple-1. Even at the "NTI" version of the Apple

this remarkable evidence from wavesoldering can

be viewed well - as seen in the rightsided picture from

the soldering side of an original NTI-version of the board.

For those who want still to view a hirespicture i have added

here a link to the entire

preNTI version and the

NTIversion.

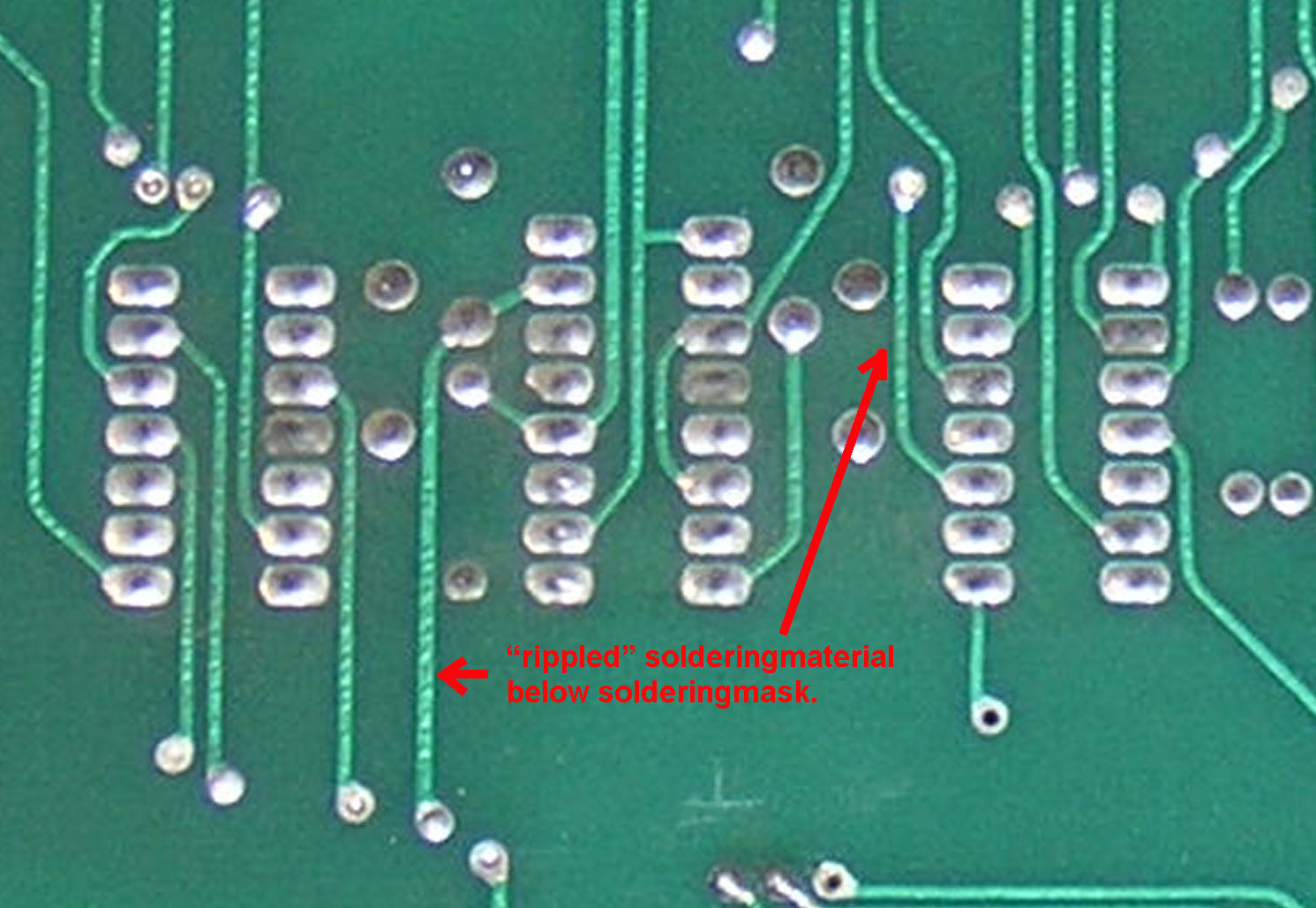

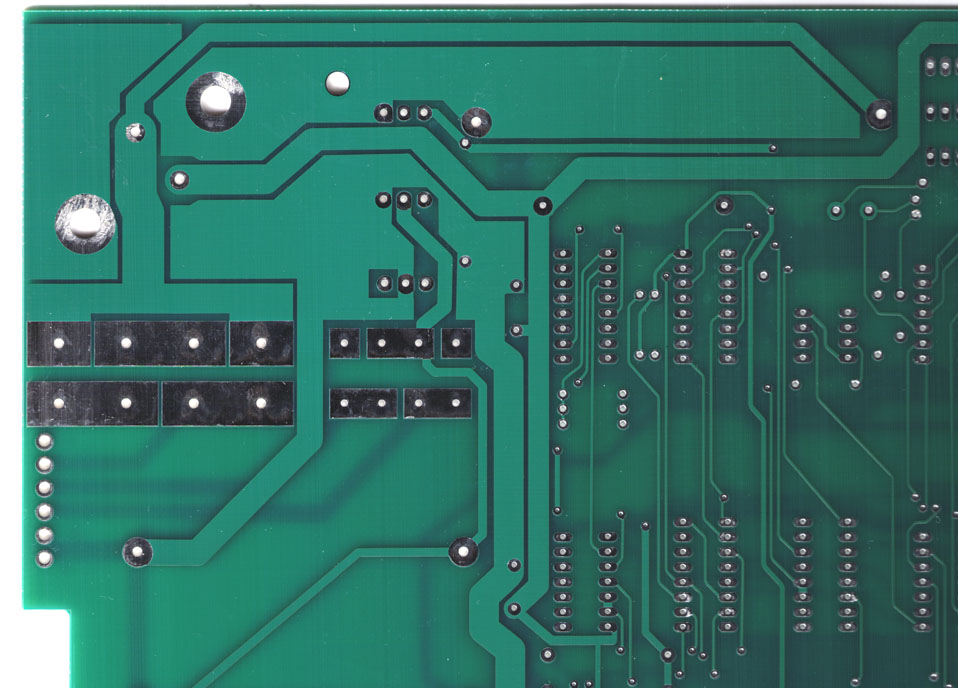

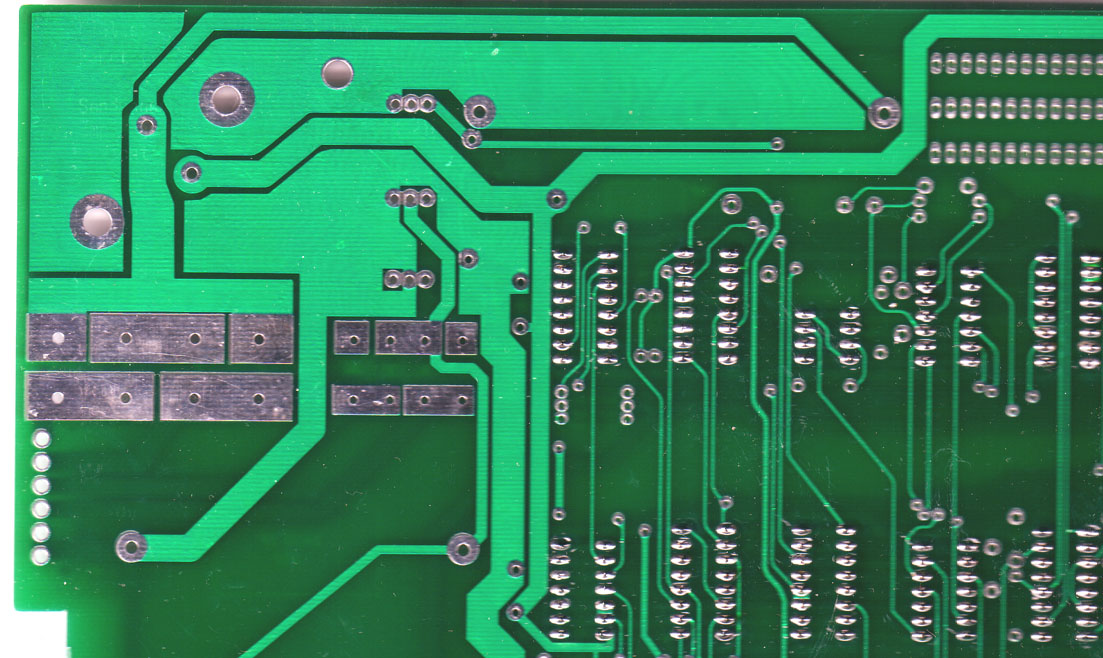

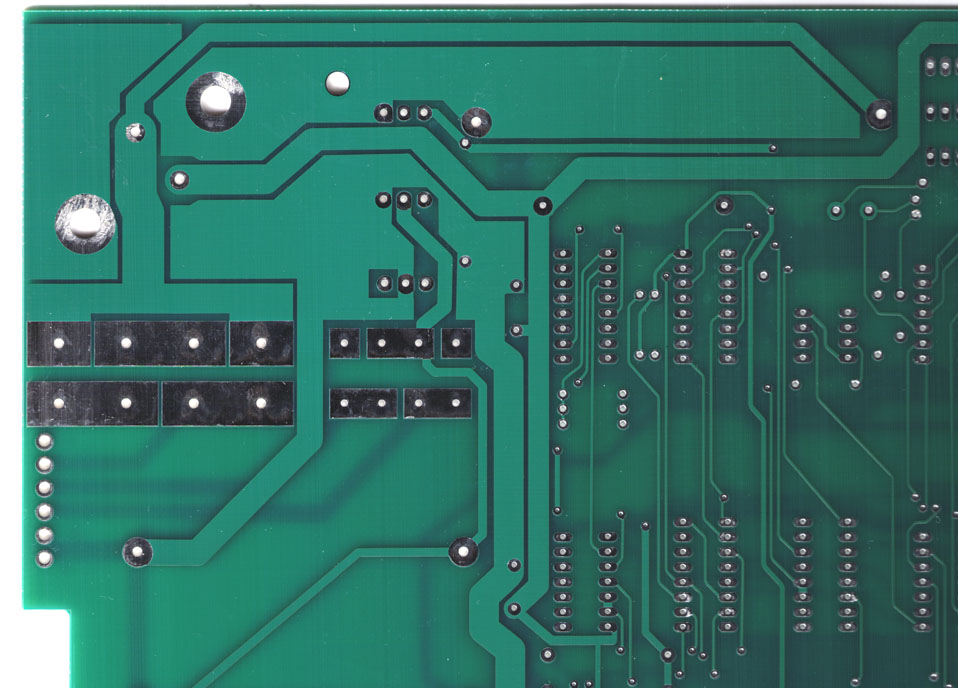

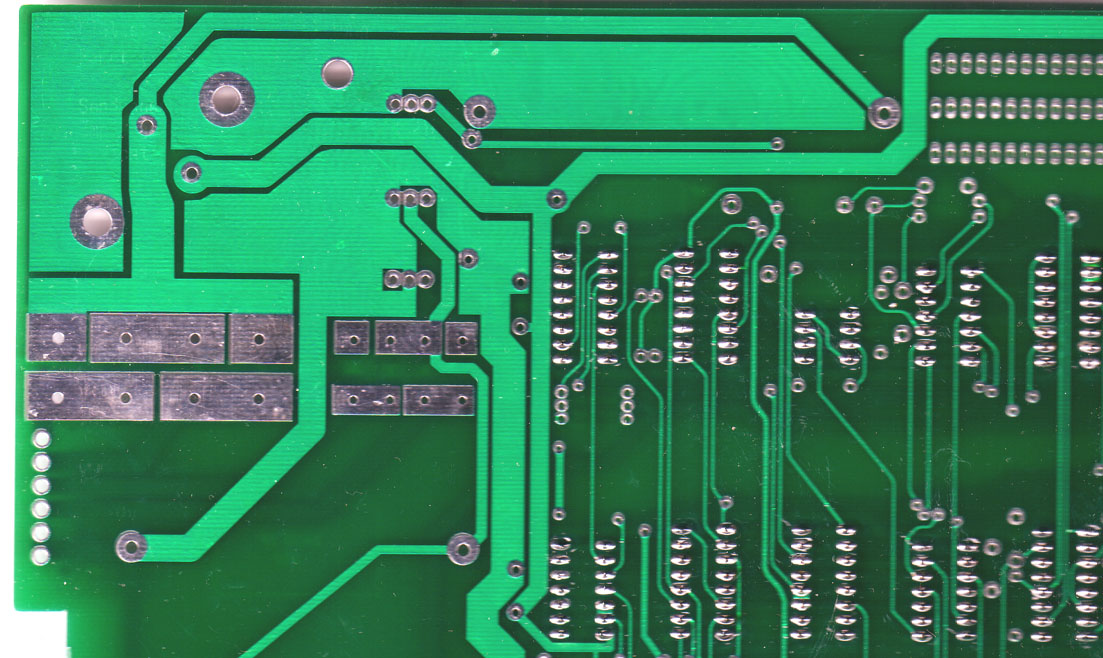

Below i display the details from a MIMEO-board scan and a

picture from a Newton NTI- board aafter the sockets only had

been soldered. Itīs easyto recognize the differences when

viewing the traces below the green soldermask. |

|

| |

Scan from part of

the MIMEO board just right after delivery |

Partial picture taken

from Newton NTI board just after soldering the sockets |

| |

|

|

So the final conclusion will be, that we can only at

least make as perfect as possible reliable soldering joints

with few soldering material as possible

- but as much material as required to result to reliable soldering

joints......

|